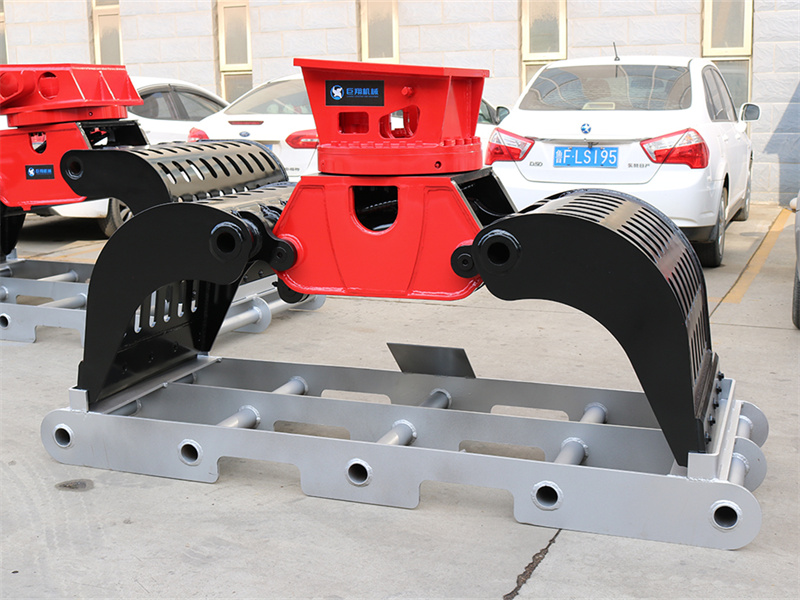

Multi Grabs

Product features

|

Model |

Unit |

CA06A |

CA08A |

|

Weight |

kg |

850 |

1435 |

|

Opening Size |

mm |

2080 |

2250 |

|

Bucket Width |

mm |

800 |

1200 |

|

Working Pressure |

Kg/cm² |

150-170 |

160-180 |

|

Setting Pressure |

Kg/cm² |

190 |

200 |

|

Working Flow |

lpm |

90-110 |

100-140 |

|

Suitable Excavator |

t |

12-16 |

17-23 |

Applications

1. **Waste Handling:** It can be used for handling waste, debris, metal fragments, and similar materials, facilitating collection, sorting, and processing.

2. **Demolition:** During building demolition, the multi grab is employed to dismantle and clear various materials such as bricks, concrete blocks, etc.

3. **Automotive Recycling:** In the automotive recycling industry, the multi grab is utilized for dismantling end-of-life vehicles, aiding in component separation and processing.

4. **Mining and Quarrying:** It's employed in quarries and mining sites for handling rocks, ores, and other materials, aiding in loading and transportation.

5. **Port and Ship Cleaning:** In port and dock environments, the multi grab is used for clearing cargo and materials from ships.

About Juxiang

| Accessoryname | Warrantyperiod | Warranty Range | |

| Motor | 12 months | It is free to replace the cracked shell and broken output shaft within 12 months. If the oil leakage occurs for more than 3 months, it is not covered by the claim. You must purchase the oil seal by yourself. | |

| Eccentricironassembly | 12 months | The rolling element and the track stuck and corroded are not covered by the claim because the lubricating oil is not filled according to the specified time, the oil seal replacement time is exceeded, and the regular maintenance is poor. | |

| ShellAssembly | 12 months | Damages caused by non-compliance with operating practices,and breaks caused by reinforce without the consent of our company,are not within the scope of claims.If Steel plate cracks within 12 months,the company will change the breaking parts;If Weld bead cracks,please weld by yourself.If you are not capable to weld,the company could weld for free,but no other expenses. | |

| Bearing | 12 months | The damage caused by poor regular maintenance, wrong operation, failure to add or replace gear oil as required or is not within the scope of claim. | |

| CylinderAssembly | 12 months | If the cylinder barrel is cracked or the cylinder rod is broken, the new component will be replaced free of charge. The oil leakage occurring within 3 months is not within the scope of claims, and the oil seal must be purchased by yourself. | |

| Solenoid Valve/throttle /check valve /flood valve | 12 months | The coil short-circuited due to external impact and the incorrect positive and negative connection is not in the scope of claim. | |

| Wiring harness | 12 months | The short circuit caused by external force extrusion, tearing, burning and wrong wire connection is not within the scope of claim settlement. | |

| Pipeline | 6 months | Damage caused by improper maintenance, external force collision, and excessive adjustment of the relief valve is not within the scope of claims. | |

| Bolts, foot switches, handles, connecting rods, fixed teeth, movable teeth and pin shafts are not guaranteed; The damage of parts caused by failure to use the company’s pipeline or failure to comply with the pipeline requirements provided by the company is not within the scope of claim settlement. | |||

Replacing the oil seal of a multi grab involves the following steps:

1. **Safety Precautions:** Ensure the machinery is turned off and any hydraulic pressure is released. Use proper personal protective equipment (PPE) such as gloves and goggles.

2. **Access the Component:** Depending on the design of the multi grab, you might need to detach certain components to access the area where the oil seal is located.

3. **Drain Hydraulic Fluid:** Before removing the oil seal, drain the hydraulic fluid from the system to prevent spillage.

4. **Remove the Old Seal:** Gently use appropriate tools to remove the old oil seal from its housing. Take care not to damage the surrounding components.

5. **Clean the Area:** Thoroughly clean the area around the oil seal housing, ensuring there is no debris or residue.

6. **Install the New Seal:** Carefully insert the new oil seal into its housing. Make sure it’s positioned correctly and fits snugly.

7. **Apply Lubrication:** Apply a thin layer of compatible hydraulic fluid or lubricant to the new seal before reassembly.

8. **Reassemble Components:** Put back any components that were removed to access the oil seal area.

9. **Refill Hydraulic Fluid:** Refill the hydraulic fluid to the recommended level using the appropriate type of fluid for your machinery.

10. **Test Operation:** Turn on the machinery and test the multi grab’s operation to ensure the new oil seal functions properly and doesn’t leak.

11. **Monitor for Leaks:** After a period of operation, closely monitor the area around the new oil seal for any signs of leakage.

12. **Regular Checks:** Incorporate checking the oil seal into your regular maintenance routine to ensure its continued effectiveness.