For owners of pile driver businesses, besides hammer malfunctions, the most troublesome and worrying issue is undoubtedly the breakage of the pile driving arm. This can result in financial losses or even serious accidents causing injury or death. Why do pile driving arms that look similar on the market vary so much in performance? Pile driving arms from small workshops, despite their thick, heavy plates and seemingly indistinguishable from those from standard construction machinery factories, often develop cracks or even break completely after 1-2 years. The secret lies in the materials, welding processes, and reduced quality control—or perhaps it’s a necessary measure taken by workshops to save costs. So why is the price of pile driving arms from workshops tens of thousands of yuan different from those from reputable factories? They capitalize on customers’ lack of understanding of manufacturing standards and their desire to buy equipment at a lower cost. The fact that these workshops cut corners on sandblasting and rust removal, chipping processes, and steel selection alone saves them approximately 20,000 yuan compared to reputable construction machinery manufacturers. The common feature of these types of pile driving arms is that safety hazards will soon appear after the warranty period, such as cracking and breakage. As a result, customers will have to pay high secondary costs, such as penalties for lost work and expenses for purchasing new arms.

As a core load-bearing component of construction machinery, the excavator piling arm must withstand high-frequency impact loads and complex stresses. Its welding quality directly determines the machine’s lifespan and operational safety. This paper takes piling arm welding as its research object, systematically analyzes its core welding process, and, combining materials science, thermodynamics, and quality control theories, explores how superior processes and industry standards fundamentally define product quality and significant cost differences.

I. Preparations Before Welding

1. Material selection and pretreatment

● Base material: High-strength low-alloy steel (such as Q-series low-alloy low-carbon wear-resistant steel or imported steel) is usually selected. It must meet the requirements of tensile strength, impact toughness and other properties. The difference in material directly leads to the difference in finished product.

● Welding Consumable Matching: Select welding wire/electrode (e.g., ER50-6, ER70S-6, etc.) according to the strength of the base metal to ensure that the mechanical properties of the deposited metal are consistent with those of the base metal, and to ensure that the strength of the deposited metal is slightly higher than that of the base metal (super-strong matching) to prevent stress concentration in the weld.

Firstly, the welding consumables required for each type of steel are completely different, and secondly, the welding temperature control also differs for each type of steel.

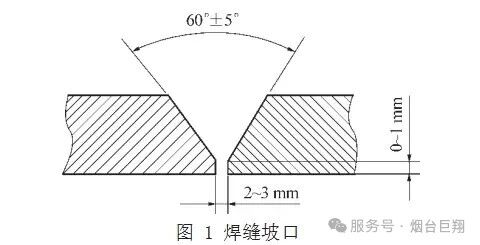

● Beveling: Beveling (V-shaped, U-shaped, or double-sided beveling) is prepared by machining or flame cutting to ensure the beveling angle, blunt edge dimensions, and cleanliness. The depth and angle of the beveling directly affect the strength of the butt weld. This step is the easiest for amateur modification shops to cut corners because the process is particularly tedious and complex, and requires a much larger amount of solder than flat welding.

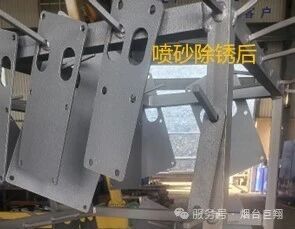

● Surface treatment: Removes oil, rust, and scale to prevent welding defects (porosity, slag inclusions).

● Sandblasting is an essential process that ensures 100% cleanliness of the welded surface.

2. Preheating and Interpass Temperature Control

● For thick plates (≥25mm) or high-carbon equivalent steel, the preheating temperature needs to reach 100~250℃ (calculated based on material thickness and carbon equivalent) to prevent cold cracking.

● The interpass temperature should be controlled above the preheating temperature but not exceeding the upper limit (e.g., Q345 steel is typically ≤250℃).

II. Welding Process Technology

1. Welding Methods

● Gas Shielded Welding (GMAW/MAG): Commonly uses CO₂ or mixed gas (Ar+CO₂) protection, high efficiency, suitable for automated welding.

● Submerged Arc Welding (SAW): Used for long, straight welds on thick plates (such as main welds on booms), with deep penetration and stable weld formation.

● Manual Arc Welding (SMAW): Used for local repairs or supplementary welding in complex locations.

● Laser-Arc Hybrid Welding (High-end Applications): Combines the advantages of laser and electric arc to improve efficiency and quality.

2. Welding Parameter Control

● Current, voltage, and welding speed need to be adjusted according to plate thickness and bevel type to ensure penetration and fusion ratio.

● When performing multi-layer, multi-pass welding, the thickness of each weld pass should be ≤4mm to avoid overheating and grain coarsening.

3. Deformation Control Technology

● Welding Sequence Optimization: Symmetrical welding, segmented back-welding, and balanced heat input.

● Tooling and Fixtures: Using rigid fixing devices to suppress deformation.

● Reverse Deformation Method: Pre-setting angle compensation opposite to welding deformation.

● Stress Relief by Hammering: Gently tapping the weld area after welding to release residual stress.

III. Post-weld Treatment and Inspection

1. Post-weld Heat Treatment

● Stress-relief annealing: For thick plates or areas with high residual stress, heat to 550~650℃ and hold for slow cooling to reduce the risk of cracking.

● Localized heat treatment: Localized heating to relieve stress in critical welds.

2. Non-destructive Testing (NDT)

● Ultrasonic Testing (UT): Detects internal defects (porosity, lack of fusion).

● Magnetic Particle Testing (MT): Inspects surface and near-surface cracks.

● Radiographic Testing (RT) (if necessary): Used to verify internal defects in important welds.

● Visual Inspection (VT): Inspects weld formation, undercut, spatter, etc.

3. Mechanical Property Testing

● Tensile Testing: Verifies weld strength.

● Impact Testing: Assessses low-temperature toughness (e.g., impact energy at -20℃ or -40℃).

● Hardness Testing: Checks if the hardness of the heat-affected zone (HAZ) exceeds the standard.

IV. Example of A Key Process (Excavator Boom Welding)

1. Material Cutting and Assembly

● CNC cutting of steel plates → beveling → assembly and tack welding (positioning welding) to ensure dimensional accuracy.

2. Main Welding

● Main welds (such as longitudinal seams inside the boom housing) are completed using submerged arc welding or automatic gas shielded welding.

● For multi-layer welding, slag is cleaned layer by layer and the fusion is checked.

3. Accessory Welding

● Accessories such as pin seats and reinforcing ribs are welded, using symmetrical welding to avoid eccentric deformation.

4. Post-Weld Correction

● Areas with excessive deformation are corrected by flame straightening or mechanical pressure straightening.

5. Pre-Painting Treatment

● Sandblasting for rust removal → cleaning → applying anti-rust primer.

V. Common Problems and Countermeasures

● Cold cracking: Strengthen preheating and post-weld insulation.

● Porosity: Ensure the purity of the protective gas and clean impurities from the bevel.

● Deformation exceeding tolerance: Optimize the welding sequence and increase tooling constraints.

Through rigorous process control and the application of advanced technologies, the reliability and long service life of welded components for construction machinery such as excavator piling arms can be ensured. Excavator piling arm welding is a deeply interdisciplinary field involving materials science, thermodynamics, and manufacturing technology. While private factories can produce products with similar appearances, they fall far short in terms of internal processes and long-life design. Furthermore, with the widespread adoption of intelligent testing equipment and digital twin technology, welding processes are shifting from experience-driven to data-driven. The process advantages of large, established factories will become increasingly significant, further achieving breakthroughs in quality control, efficiency, and sustainability. The selection of a piling arm is a commercial transaction that tests the industry’s understanding and capabilities.

Post time: Jan-05-2026