Many people think machining is just machining, and that hand-cut construction machinery parts and machined parts are equally usable. Are they really that similar? Not really. Imagine why machined parts manufactured in Japan and Germany are of higher quality. In addition to sophisticated machine tools, they also rely on strict standards and processes. Today, let’s start with the first step: flame cutting.

1.1 Process Overview

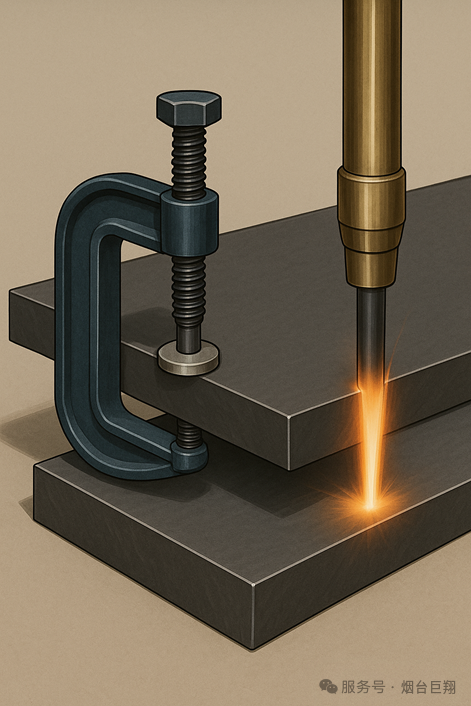

Flame cutting is the first raw material processing step in excavator boom manufacturing and the first step in plate processing for most construction machinery. Its primary purpose is to precisely divide large steel plates into various components for subsequent forming, including main beam outer plates, inner reinforcement plates, and trunnion seat plates, according to design requirements.

This process utilizes CNC oxygen-fuel cutting equipment, which generates a high-temperature flame using an oxygen-acetylene mixture to partially melt and oxidize the carbon steel plate.

1.2 Device Configuration

● CNC flame cutting machine (benchtop/gantry)

● Automatic programming and trajectory control system (based on CAD drawings)

● Oxygen and acetylene gas supply system

● Automatic torch lift and flame temperature control module

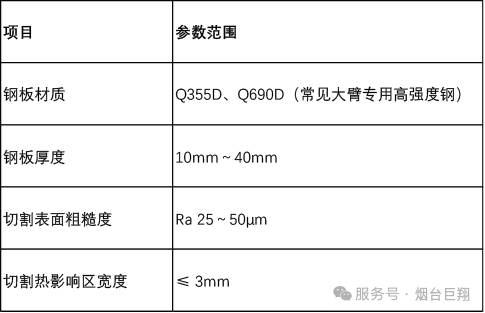

1.3 Material Parameters

1.4 Process

1) Preparation before cutting

● Check that the steel plate material and dimensions are consistent with the design drawings;

● Remove oil, moisture, and rust from the steel plate surface.

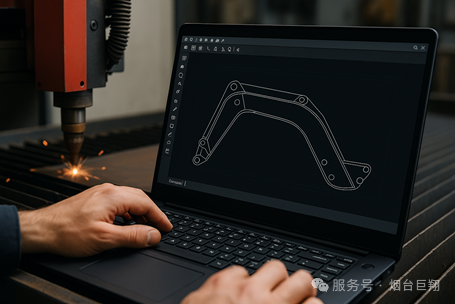

2) Programming and typesetting

● Import CAD designs into the CNC cutting system;

● Perform intelligent nesting to optimize material utilization;

● Set the cutting order, prioritizing small parts to large parts to prevent thermal deformation.

3) Equipment debugging

● Calibrate trajectory accuracy;

● Set flame gas pressure (0.4-0.6 MPa for oxygen, 0.01-0.05 MPa for acetylene);

● Adjust the initial gap between the cutting torch and the steel plate (3-5 mm).

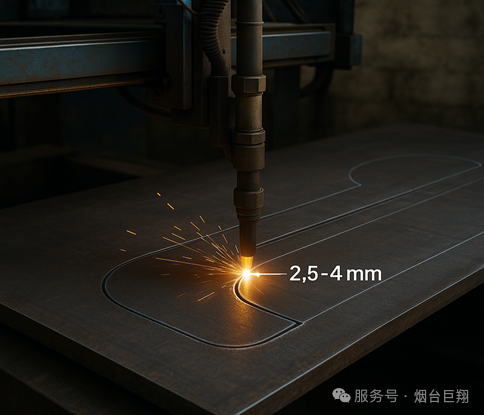

4) Flame cutting execution

● Ignition preheats to the material’s ignition point;

● The cutting head automatically moves along a trajectory, while flame cutting proceeds simultaneously;

● Maintains a stable kerf width (usually 2.5mm to 4mm) to prevent uneven burning.

5) Quality inspection

● Visually inspect the cut straightness and surface cleanliness;

● Use an ultrasonic thickness gauge to confirm the depth of the heat-affected zone in key areas;

● Check the dimensional tolerance of the cut parts (generally ≤±1.5mm).

6) Post-processing

● Manually remove cutting burrs;

● Clean the oxide scale to prevent subsequent welding pores.

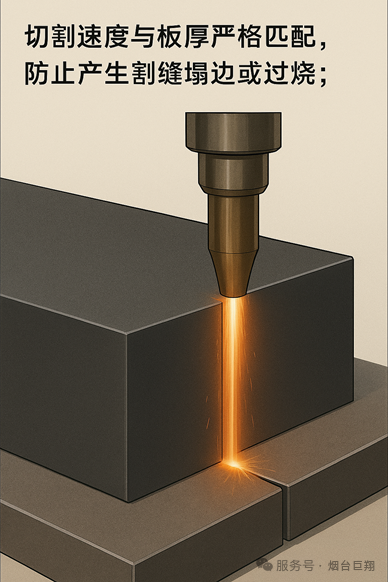

1.5 Technical Points and Precautions

● The cutting speed is strictly matched to the plate thickness to prevent the cutting edge from collapsing or overburning;

● The steel plate must be clamped stably to avoid vibration during cutting that could cause deviation in the cutting path.

● For thick plates over 40mm, a multi-stage flame preheating strategy should be used to improve kerf verticality.

● Maintain an oxygen purity of ≥99.5%, otherwise the smoothness of the cut surface will be affected.

● During production, flame temperature changes should be monitored in real time to adjust the gas ratio promptly.

The above is the first step in the machining of construction machinery excavators, flame cutting.

Post time: Jul-31-2025