In the manufacturing process of the excavator arm, “plate leveling and beveling” is a very critical basic process in the whole process. Although it is not the most conspicuous link, it is like the foundation treatment before building a house, which determines whether the subsequent welding, assembly, and dimensional accuracy can be “smoothly on track”.

Today we will talk about what this step is doing, how to do it, and why it cannot be saved.

3.1 Why is leveling necessary?

Why do we need to “level”? Isn’t the steel plate flat after cutting?

Actually, it is not.

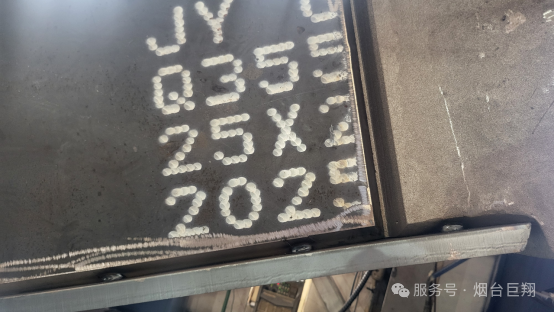

After flame or plasma cutting, the steel plate will have obvious wave deformation, thermal stress warping or corner distortion. These seemingly small deformations, in the excavator boom, extension arm, pile driving arm and other structural parts that are more than 10 meters long and bear several tons of weight, even a deviation of 2 mm may cause:

· Weld seam “misalignment” and undercut;

· Subsequent assembly does not match the hole;

· Residual stress concentration after welding, even “cracks” after a few years of use.

Therefore, the steel plate must be repeatedly pressed using a leveling machine and multiple sets of upper and lower rollers to eliminate internal stress and restore flatness.

Key points of leveling:

· The flatness of the steel plate should be controlled within ±2mm/m;

· Both sides of the steel plate should be pressed at the same time to avoid reverse warping;

· For thicker steel plates (>20mm), it is necessary to level them repeatedly in sections, and it is not possible to “press them all the way to the bottom in one go”.

3.2 What is “slope opening”?

What is “beveling”? Why do we need to bevel the edge of the plate?

Simply put: to make the weld stronger.

Ordinary steel plates have straight edges. If they are directly butt welded, the penetration depth is not enough and the weld is unstable. Moreover, the metal cannot be fully fused, which easily leads to welding defects such as cold welding, slag inclusions, and pores.

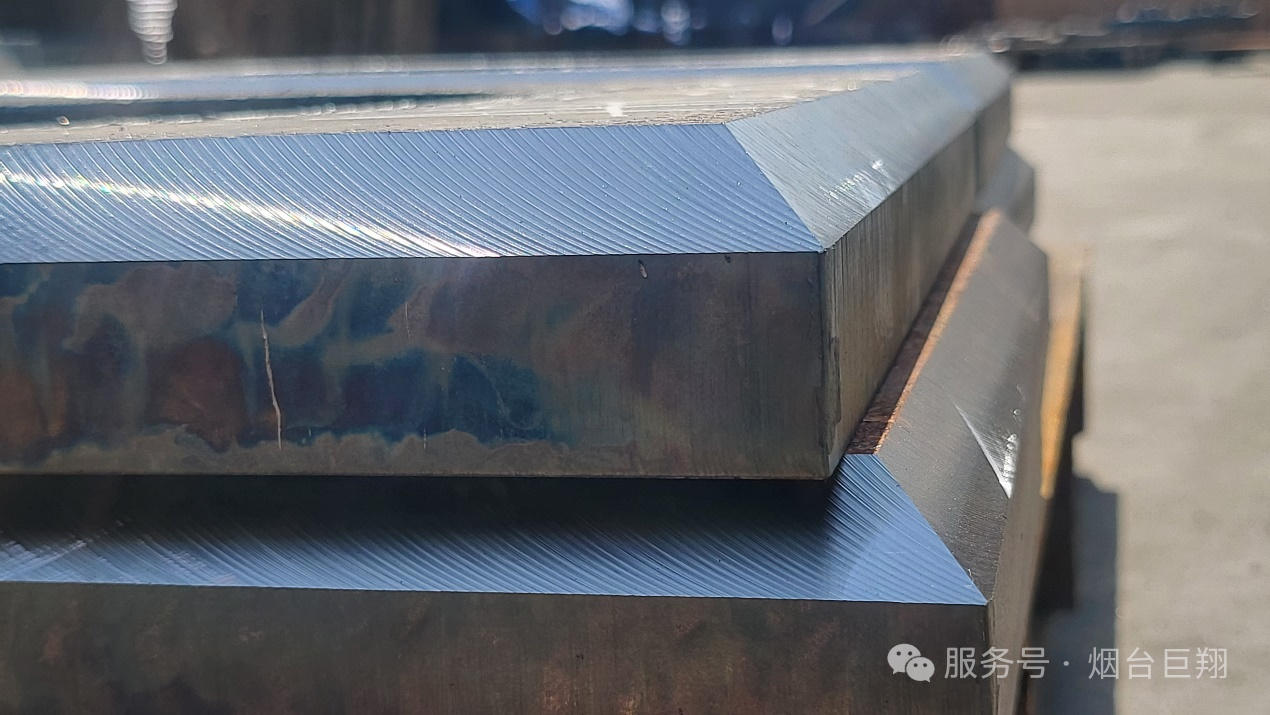

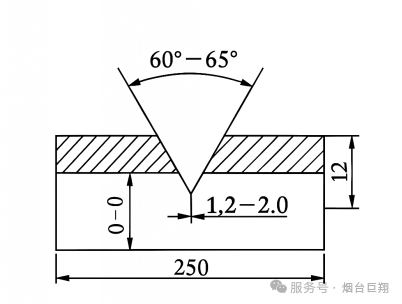

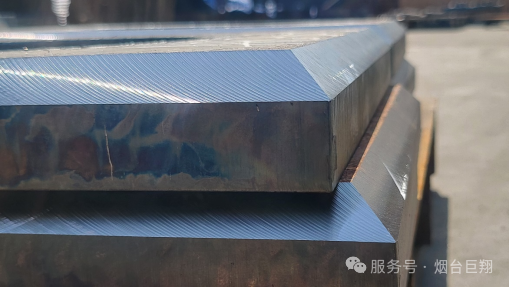

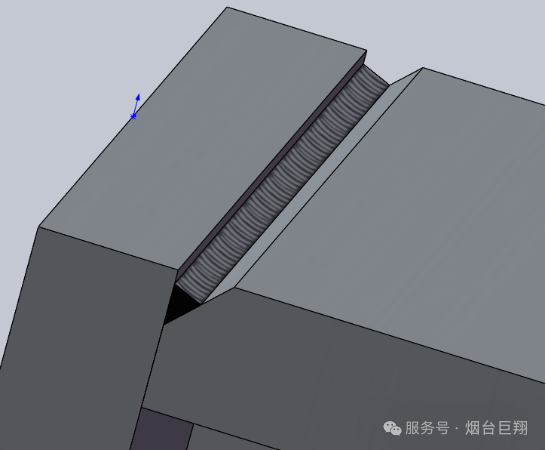

Therefore, the plate edge should be processed into a V-shaped, X-shaped or U-shaped notch so that the welding rod or wire can penetrate to the bottom and “bite” the two plate edges.

Common groove forms:

Single-sided V-shaped is one side inclined, applicable to thickness less than or equal to 20mm; double-sided X-shaped is two sides symmetrically inclined, applicable to thickness 20-40mm; K-shaped and U-shaped are applicable to extra thick plates, thickness greater than or equal to 40mm.

The general control of groove parameters:

· Angle: 30°~45° on one side, symmetrical angle not exceeding 65°

· Blunt edge: 2~4mm

· “Corner collapse”, “edge tearing” and “burn-through” are not allowed

Processing methods:

· Batch straight plate edge → CNC flame/plasma beveling cutting machine

· Local special-shaped parts → carbon arc gouging + grinding

· High precision → CNC milling machine/robot beveling cutting

3.3 Reasonable beveling process

A reasonable groove process is to prepare for reasonable multi-layer welding and increase the solder capacity and number of layers for the weld. What will happen if this step is not done well?

· Large welding deformation: The shrinkage force of the weld will “pull the entire component crooked”

· Difficult assembly: The hole position is not aligned, and the connector cannot be installed

· Fatigue cracking: Residual stress + welding defects, structural fracture within a few years

· Increased costs: Rework, grinding, rework, or even scrapping an entire arm

Therefore, it is often said in the industry: “If the plate is not leveled and the groove is not done well, no matter how good the welder is, it will be useless.”

In one sentence:

“Plate leveling + beveling” is the first step to improve welding quality and the starting point for the boom to go from “welding capable” to “welding stably”.

It may not be glamorous, but without it, all subsequent accuracy, strength, and safety will become empty talk.

Post time: Jun-12-2025