In the vast galaxy of construction machinery, there is a shining star – Juxiang Machinery. It uses innovation as its sail and quality as its paddle to forge ahead in the tide of the industry. Today, let us open the door of Juxiang Machinery and explore the legendary story behind it.

2.1 Process Overview

Sheet metal bending is a key step in the manufacturing process of excavator booms. Its main task is to mechanically bend or roll the flame-cut plates to initially form the geometric outline of the boom main beam and reinforcement structure, providing accurate basic dimensions and spatial shapes for subsequent welding and assembly processes.

This process has extremely high requirements for material ductility, equipment control accuracy, and bending parameter settings, which directly affects the ultimate load-bearing capacity and fatigue life of the boom.

2.2 Device Configuration

· Large hydraulic press brake or plate rolling machine

· Specialized bending molds (V-type, R-type, special-shaped molds)

· Positioning fixture and auxiliary support system

· Digital angle measuring instrument/three-coordinate measuring instrument (optional)

2.3 Material Requirements

1. Steel plate material: Q355D, Q690D, WEL-TEN590 and other structural high-strength steels

2. Steel plate state: Natural cooling after flame cutting, large-area thermal warping is not allowed

3. Plate thickness bending ratio: Minimum inner bending radius ≥ plate thickness × 1.5 (high-strength steels such as Q690D have stricter requirements)

2.4 Process Flow

1) Material Pretreatment

· Check that the surface of the cut piece is clean and has no large area of burrs;

· If necessary, locally grind the oxide film on the cut to improve the surface quality of the bending.

2) Process Parameter Setting

· Determine the bending force (Ton/m) according to the material and thickness of the steel plate;

· Select the appropriate lower die opening size and upper die radius;

· Set the bending rebound compensation parameters (especially high-strength steel Q690D requires an appropriate overbending angle).

3) Bending Operation

· Bend once or multiple times with a hydraulic press brake to gradually reach the target angle;

· Roller bending machine is used for rounding of large curvature components;

· The angle and shape deviation should be measured synchronously during the bending process and adjusted in time.

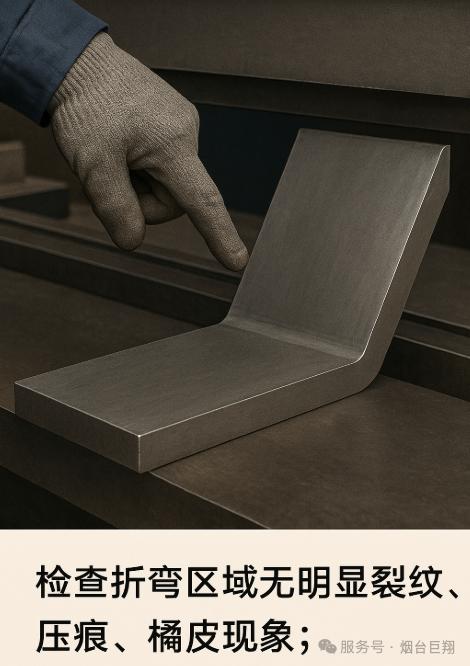

4) Semi-finished Product Inspection

· Use a special template or gauge to detect the bending angle;

· Check that there are no obvious cracks, indentations, or orange peel in the bending area;

· The external dimension tolerance is controlled within ±2 mm.

2.5 Technical Points & Precautions

· It is recommended to preheat high-strength steel (120℃~180℃) before bending to reduce the risk of cold brittle fracture;

· The bending direction should be preferably along the rolling direction of the steel plate to reduce the probability of cracking;

· The segmented bending should maintain a smooth transition and no obvious creases should be formed;

· It is strictly forbidden to repeatedly bend back in the bending area to prevent material fatigue cracking;

· After bending, hammering adjustment is prohibited. If there is an error, it should be adjusted through the equipment bend back process;

· The equipment stroke controller and limit protection device must be calibrated before operation.

2.6 Special Instructions (Applicable to Large-tonnage Excavator Booms)

· For the steel plates of the boom main beam of excavators of 40 tons and above, the “multiple progressive bending method” combined with neutral line compensation is often used to ensure the consistency of the overall curvature;

· For ultra-high strength steel plates (tensile strength ≥ 900MPa), a combined process of segmented roller bending + local rebound correction is required;

· The reinforcement plate in the boom ear shaft area usually reserves some margin, and is precisely positioned by machining after bending.

The above is the second chapter of the series “The Journey of a Steel Plate – The Birth of the Excavator Boom” (to be continued)

Post time: May-21-2025