Ntau tus neeg xav tias machining tsuas yog machining xwb, thiab cov khoom siv txiav tes txiav thiab cov khoom siv tau sib npaug. Puas yog lawv zoo sib xws? Tsis yog tiag. Xav txog yog vim li cas machined qhov chaw tsim nyob rau hauv Nyiv thiab lub teb chaws Yelemees yog cov zoo dua. Ntxiv nrog rau cov cuab yeej siv tshuab zoo, lawv kuj tso siab rau cov qauv nruj thiab cov txheej txheem. Hnub no, cia peb pib nrog thawj kauj ruam: nplaim taws txiav.

1.1 Txheej txheem txheej txheem

Nplaim txiav yog thawj cov khoom siv raw ua cov kauj ruam hauv excavator boom manufacturing thiab thawj kauj ruam hauv kev ua phaj rau feem ntau siv tshuab. Nws lub hom phiaj tseem ceeb yog kom meej meej faib cov hlau loj loj rau hauv ntau yam khoom siv rau kev tsim tom ntej, suav nrog cov kab hluav taws xob sab nrauv, cov phaj sab hauv, thiab cov phaj trunnion, raws li cov qauv tsim.

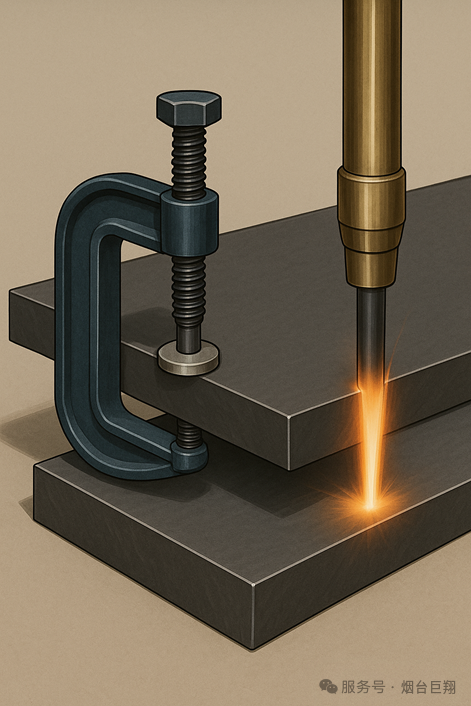

Cov txheej txheem no siv CNC oxygen-roj txiav cov cuab yeej, uas tsim cov nplaim hluav taws kub uas siv cov pa oxygen-acetylene sib tov rau ib nrab yaj thiab oxidize cov pa roj carbon steel phaj.

1.2 Device Configuration

● CNC nplaim taws txiav tshuab (benchtop / gantry)

● Tsis siv neeg programming thiab trajectory tswj system (raws li CAD kos duab)

● Oxygen thiab acetylene gas mov system

● Tsis siv neeg lub teeb nqa thiab nplaim taws kub tswj module

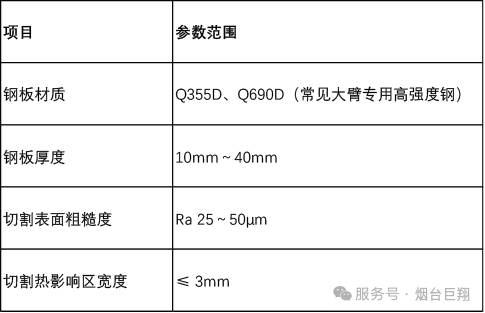

1.3 Khoom Parameters

1.4 Txheej txheem

1) Kev npaj ua ntej txiav

● Tshawb xyuas tias cov khoom siv steel phaj thiab qhov ntev yog raws li cov qauv kos duab;

● Tshem tawm cov roj, noo noo, thiab xeb los ntawm steel phaj nto.

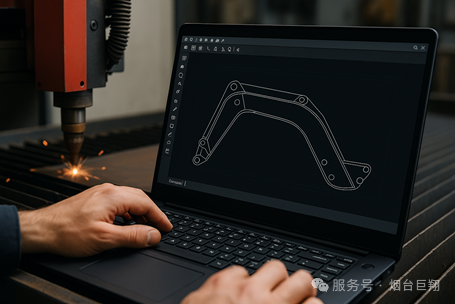

2) Programming thiab typeetting

● Ntshuam CAD tsim rau hauv CNC txiav system;

● Ua lub zes ntse kom txhim kho kev siv cov khoom siv;

● Teem lub txiav txiav, ua ntej qhov me me rau qhov loj kom tiv thaiv thermal deformation.

3) Cov cuab yeej debugging

● Calibrate trajectory raug;

● Teem nplaim taws siab (0.4-0.6 MPa rau oxygen, 0.01-0.05 MPa rau acetylene);

● Kho qhov sib txawv ntawm qhov sib txawv ntawm qhov hluav taws xob txiav thiab cov phaj hlau (3-5 hli).

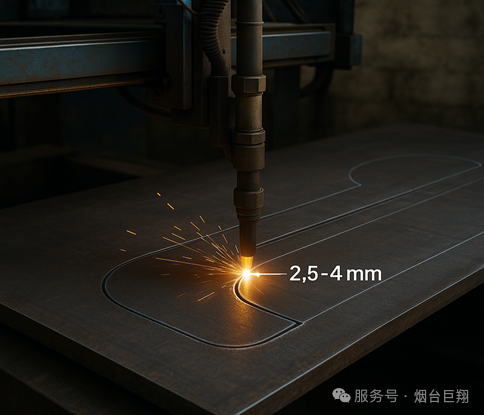

4) Nplaim txiav ua tiav

● Ignition preheats rau cov khoom ignition point;

● Lub taub hau txiav txiav txav mus raws ib txoj hauv kev, thaum cov nplaim hluav taws ua tiav ib txhij;

● Ua kom ruaj khov kerf dav (feem ntau yog 2.5mm txog 4mm) kom tsis txhob muaj qhov kub tsis sib xws.

5) Kev soj ntsuam zoo

● Visually soj ntsuam qhov txiav ncaj thiab deg huv si;

● Siv lub ntsuas ntsuas ntsuas ultrasonic kom paub meej tias qhov tob ntawm thaj chaw kub ntxhov hauv thaj chaw tseem ceeb;

● Txheeb xyuas qhov ntev ntev ntawm qhov txiav (feem ntau ≤ ± 1.5mm).

6) Tom qab ua tiav

● Manually tshem tawm tej burrs;

● Ntxuav cov nplai oxide kom tiv thaiv qhov welding tom ntej.

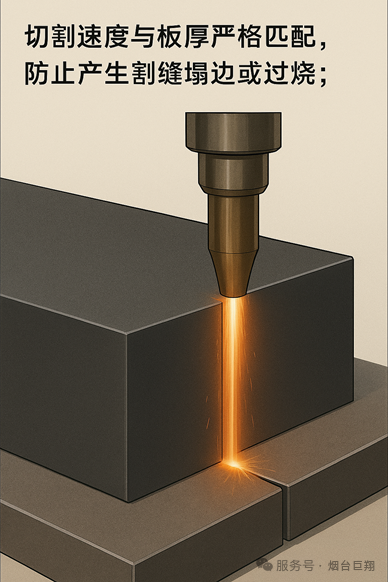

1.5 Cov ntsiab lus technical thiab ceev faj

● Lub txiav ceev yog nruj me ntsis sib phim rau lub phaj thickness los tiv thaiv qhov txiav ntug ntawm kev sib tsoo los yog overburning;

● Cov phaj hlau yuav tsum tau clamped stably kom tsis txhob muaj kev vibration thaum txiav uas yuav ua rau deviation nyob rau hauv txoj kev txiav.

● Rau cov phaj tuab tshaj 40mm, yuav tsum tau siv ntau theem hluav taws kub preheating zoo los txhim kho kerf verticality.

● Tuav cov pa purity ntawm ≥99.5%, txwv tsis pub lub smoothness ntawm qhov chaw txiav yuav raug cuam tshuam.

● Thaum lub sij hawm tsim khoom, cov nplaim hluav taws kub hloov yuav tsum tau saib xyuas hauv lub sijhawm tiag tiag los kho cov roj sib piv tam sim.

Cov saum toj no yog thawj kauj ruam hauv machining ntawm kev tsim kho tshuab excavators, nplaim taws txiav.

Post lub sij hawm: Lub Xya hli ntuj-31-2025