Nyob rau hauv cov txheej txheem ntawm excavator caj npab, "phaj leveling thiab beveling" yog ib qho tseem ceeb heev txheej txheem nyob rau hauv tag nrho cov txheej txheem. Txawm hais tias nws tsis yog qhov pom tseeb tshaj plaws, nws zoo li lub hauv paus kev kho mob ua ntej tsim lub tsev, uas txiav txim siab seb qhov kev sib txuas tom ntej, kev sib dhos, thiab qhov tseeb ntawm qhov yuav ua tau "nruab nrab ntawm txoj kev".

Niaj hnub no peb yuav tham txog dab tsi cov kauj ruam no ua, yuav ua li cas, thiab yog vim li cas nws yuav cawm tsis tau.

3.1 Vim li cas thiaj li tsim nyog?

Vim li cas peb thiaj li yuav tsum "theem"? Tsis yog steel phaj tiaj tom qab txiav?

Qhov tseeb, tsis yog.

Tom qab nplaim taws lossis ntshav txiav, cov phaj hlau yuav muaj qhov pom tseeb yoj deformation, thermal stress warping los yog ces kaum distortion. Cov zoo li me me deformations, nyob rau hauv lub excavator boom, extension caj npab, pawg tsav tsheb caj npab thiab lwm yam structural qhov chaw uas muaj ntau tshaj 10 meters ntev thiab dais ob peb tons ntawm qhov hnyav, txawm tias ib tug sib txawv ntawm 2 hli yuav ua rau:

· Weld seam "misalignment" thiab undercut;

· Kev sib dhos tom qab tsis sib xws ntawm lub qhov;

· Residual stress concentration tom qab vuam, txawm tias "kawg" tom qab siv ob peb xyoos.

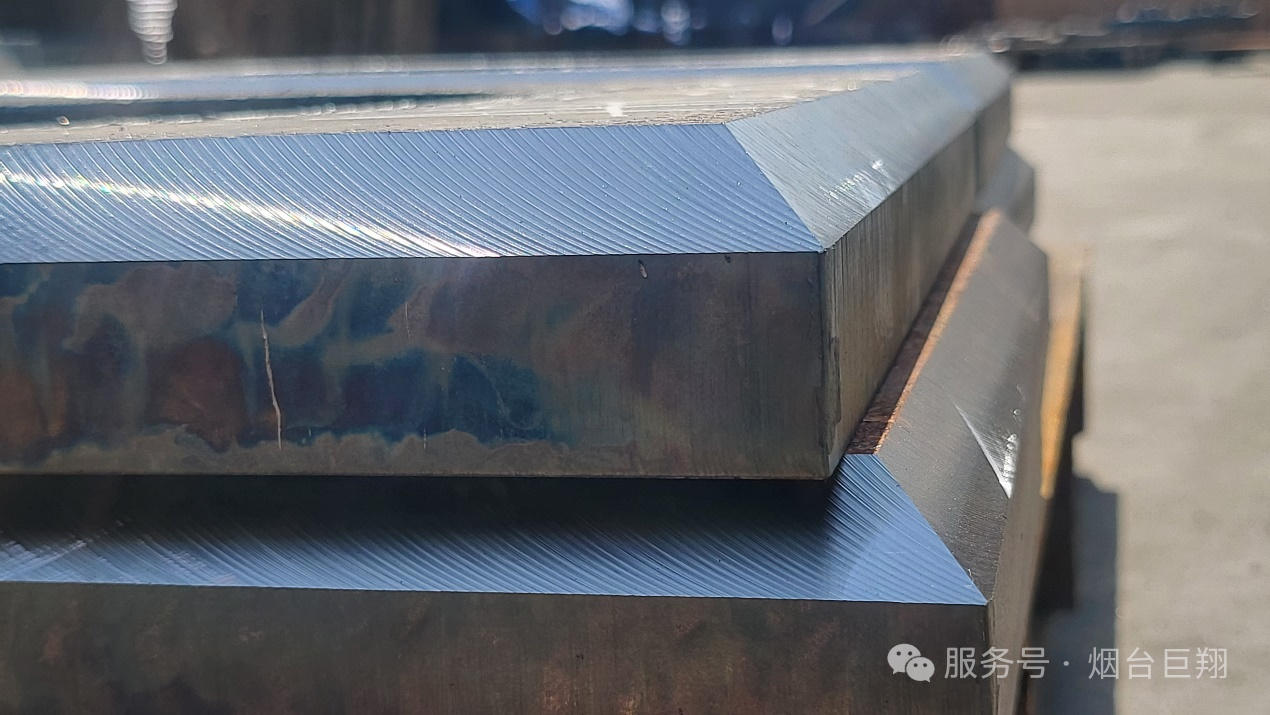

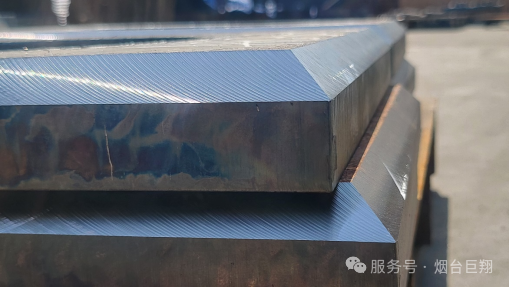

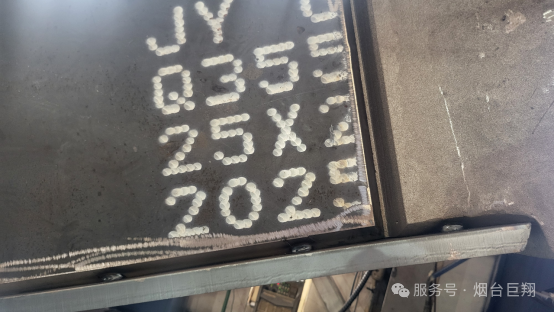

Yog li ntawd, cov hlau phaj yuav tsum tau rov nias dua siv lub tshuab leveling thiab ntau cov txheej txheem ntawm sab sauv thiab qis dua kom tshem tawm cov kev ntxhov siab sab hauv thiab rov ua kom flatness.

Cov ntsiab lus tseem ceeb ntawm leveling:

· Lub flatness ntawm steel phaj yuav tsum tau tswj nyob rau hauv ± 2mm / m;

· Ob sab ntawm lub phaj hlau yuav tsum tau nias tib lub sij hawm kom tsis txhob rov qab warping;

· Rau cov hlau phaj tuab (> 20mm), nws yog ib qho tsim nyog yuav tsum tau ua kom lawv rov ua dua hauv ntu, thiab nws tsis tuaj yeem "nias lawv mus rau hauv qab hauv ib qho mus".

3.2 "Kev qhib txoj kab nqes" yog dab tsi?

"beveling" yog dab tsi? Vim li cas peb yuav tsum tau bevel ntug ntawm lub phaj?

Yooj yim muab: ua kom lub vuam muaj zog.

Ordinary steel phaj muaj cov npoo ncaj. Yog hais tias lawv tau ncaj nraim pob tw welded, qhov tob tob tob tsis txaus thiab qhov vuam tsis ruaj khov. Ntxiv mus, cov hlau tsis tuaj yeem raug fused tag nrho, uas yooj yim ua rau vuam tsis xws luag xws li txias vuam, slag inclusions, thiab pores.

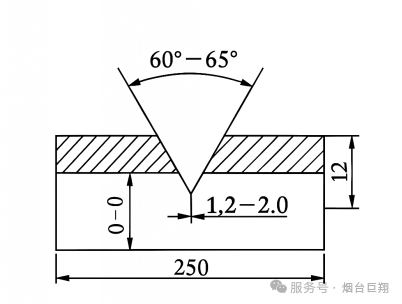

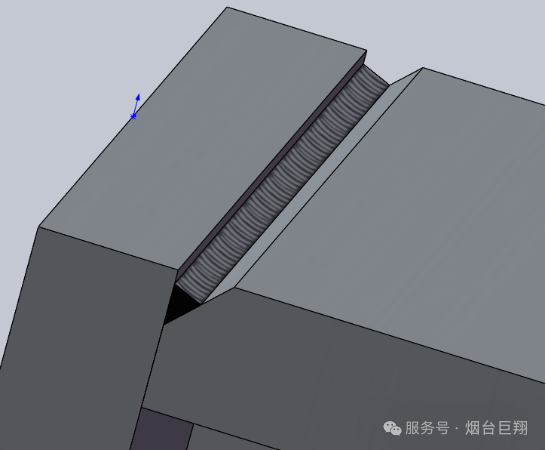

Yog li ntawd, lub phaj ntug yuav tsum tau ua tiav rau hauv V-shaped, X-shaped lossis U-shaped thais kom lub vuam pas nrig lossis hlau tuaj yeem nkag mus rau hauv qab thiab "tom" ob lub phaj npoo.

Common groove forms:

Ib sab V-shaped yog ib sab inclined, muaj feem xyuam rau thickness tsawg dua los yog sib npaug li 20 hli; ob sab X-puab yog ob sab symmetrically inclined, muaj feem xyuam rau thickness 20-40mm; K-shaped thiab U-puab yog siv tau rau cov phaj tuab ntxiv, thickness ntau dua lossis sib npaug li 40mm.

General tswj ntawm groove parameters:

· Lub kaum sab xis: 30 ° ~ 45 ° ntawm ib sab, symmetrical lub kaum sab xis tsis tshaj 65 °

· Blunt ntug: 2 ~ 4mm

· Tsis pub "pob tawg", "ntug tearing" thiab "hlawv-dhau" tsis raug tso cai

Cov txheej txheem ua:

· Batch ncaj phaj ntug → CNC nplaim/plasma beveling txiav tshuab

· Cov khoom tshwj xeeb hauv zos → carbon arc gouging + sib tsoo

· High precision → CNC milling tshuab / neeg hlau beveling txiav

3.3 Tsim nyog beveling txheej txheem

Cov txheej txheem groove tsim nyog yog los npaj rau kev tsim nyog ntau txheej vuam thiab ua kom muaj peev xwm thiab cov txheej txheem ntau lawm rau cov vuam. Yuav ua li cas yog tias cov kauj ruam no ua tsis tau zoo?

· Loj vuam deformation: Lub shrinkage quab yuam ntawm weld yuav "rub tag nrho cov khoom crooked"

· Kev sib dhos nyuaj: Qhov txoj hauj lwm ntawm lub qhov tsis sib haum, thiab lub connector tsis tuaj yeem ntsia tau

· Kev qaug zog tawg: Kev ntxhov siab seem + vuam tsis xws luag, kev puas tsuaj hauv ob peb xyoos

· Cov nqi nce ntxiv: Rov ua dua, sib tsoo, rov ua dua, lossis txawm tias khawb tag nrho caj npab

Yog li ntawd, nws yog feem ntau hais nyob rau hauv kev lag luam: "Yog hais tias lub phaj tsis leveled thiab zawj tsis ua zoo, txawm li cas los xij zoo li tus welder, nws yuav tsis muaj txiaj ntsig."

Hauv ib kab lus:

"Plate leveling + beveling" yog thawj kauj ruam los txhim kho vuam zoo thiab pib qhov chaw rau qhov boom mus ntawm "welding muaj peev xwm" mus rau "welding stably".

Tej zaum nws yuav tsis zoo nkauj, tab sis yog tsis muaj nws, tag nrho cov tom ntej raug, lub zog, thiab kev nyab xeeb yuav dhau los ua lus tsis muaj.

Post lub sij hawm: Jun-12-2025