Nyob rau hauv lub galaxy loj ntawm kev tsim kho tshuab, muaj lub hnub qub ci ntsa iab - Juxiang Machinery. Nws siv innovation raws li nws sail thiab zoo raws li nws paddle rau forge ua ntej nyob rau hauv lub tide ntawm kev lag luam. Hnub no, cia peb qhib qhov rooj ntawm Juxiang Machinery thiab tshawb txog cov dab neeg dab neeg tom qab nws.

2.1 Txheej txheem txheej txheem

Sheet hlau dabtsi yog khoov yog cov kauj ruam tseem ceeb hauv kev tsim cov txheej txheem excavator booms. Nws lub luag haujlwm tseem ceeb yog khoov los yog yob cov nplaim-txiav daim hlau los pib tsim cov duab geometric ntawm cov nqaj loj thiab cov qauv siv zog, muab qhov tseeb qhov ntev thiab cov duab spatial rau cov txheej txheem vuam thiab sib dhos.

Cov txheej txheem no muaj cov kev xav tau siab heev rau cov khoom siv ductility, cov cuab yeej tswj xyuas qhov tseeb, thiab khoov qhov ntsuas qhov ntsuas, uas cuam tshuam ncaj qha rau qhov kawg ntawm lub peev xwm thauj khoom thiab qaug zog lub neej ntawm boom.

2.2 Device Configuration

· Loj hydraulic xovxwm nres lossis phaj dov tshuab

· Tshwj xeeb dabtsi yog khoov pwm (V-hom, R-hom, tshwj xeeb-puab pwm)

· Muab tso rau fixture thiab pab txhawb system

· Lub kaum ntse ntse ntsuas ntsuas / peb-coordinate ntsuas ntsuas (yeem)

2.3 Cov ntaub ntawv xav tau

1. Cov khoom siv hlau phaj: Q355D, Q690D, WEL-TEN590 thiab lwm yam khoom muaj zog steels

2. Steel phaj xeev: Lub ntuj txias tom qab nplaim taws txiav, thaj chaw loj thermal warping tsis raug tso cai

3. Phaj thickness dabtsi yog khoov piv: Yam tsawg kawg yog puab bending vojvoog ≥ phaj thickness × 1.5 (high-strength steels xws li Q690D muaj stricter yuav tsum tau)

2.4 Txheej txheem Flow

1) Khoom Pretreatment

· Xyuas kom meej tias qhov chaw ntawm qhov txiav yog huv si thiab tsis muaj qhov loj ntawm burrs;

· Yog tias tsim nyog, hauv zos zom cov oxide zaj duab xis ntawm qhov txiav kom txhim kho qhov zoo ntawm qhov khoov.

2) Txheej Txheem Txheej Txheem

· Txiav txim siab dabtsi yog khoov quab yuam (Ton / m) raws li cov khoom thiab thickness ntawm steel phaj;

· Xaiv qhov tsim nyog qhov qhib qhov loj me thiab lub vojvoog tuag sab saud;

· Teem lub bending rebound tsis them nyiaj (tshwj xeeb tshaj yog high-strength steel Q690D yuav tsum tau ib tug tsim nyog overbending kaum).

3) Kev ua haujlwm dabtsi yog khoov

· Khoov ib zaug lossis ntau zaus nrog hydraulic xovxwm nres kom maj mam ncav cuag lub hom phiaj;

· Roller dabtsi yog khoov tshuab yog siv rau rounding ntawm loj curvature Cheebtsam;

· Lub kaum sab xis thiab cov duab sib txawv yuav tsum tau ntsuas synchronously thaum lub sijhawm khoov thiab kho raws sijhawm.

4) Semi-tiav khoom soj ntsuam

· Siv cov qauv tshwj xeeb lossis ntsuas ntsuas kom pom lub kaum sab xis;

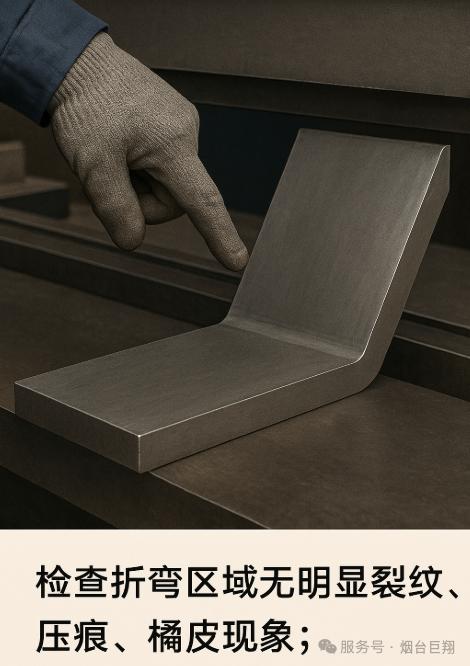

· Xyuas kom paub tseeb tias tsis muaj kab nrib pleb, indentations, lossis txiv kab ntxwv tev nyob rau hauv qhov chaw khoov;

· Sab nraud qhov kam rau ua yog tswj tsis pub dhau ± 2 hli.

2.5 Cov ntsiab lus technical & ceev faj

· Nws raug nquahu kom preheat high-strength steel (120 ℃ ~ 180 ℃) ua ntej khoov kom txo tau qhov kev pheej hmoo ntawm kev mob khaub thuas tawg;

· Cov kev taw qhia dabtsi yog khoov yuav tsum zoo dua raws li cov kev taw qhia dov ntawm cov hlau phaj kom txo tau qhov tshwm sim ntawm kev tawg;

· Lub segmented dabtsi yog khoov yuav tsum tswj ib tug du thiab tsis pom tseeb creases yuav tsum tau tsim;

· Nws yog nruj me ntsis txwv tsis pub rov khoov rov qab rau hauv qhov chaw khoov kom tiv thaiv cov khoom qaug zog tawg;

· Tom qab khoov, kev kho rau hammering yog txwv tsis pub. Yog tias muaj qhov yuam kev, nws yuav tsum tau kho los ntawm cov khoom siv khoov rov qab txheej txheem;

· Cov cuab yeej siv hluav taws xob tswj thiab txwv kev tiv thaiv yuav tsum tau ntsuas ua ntej ua haujlwm.

2.6 Cov lus qhia tshwj xeeb (tseem siv tau rau loj-tonnage Excavator Booms)

· Rau cov hlau daim hlau ntawm boom lub ntsiab nqaj ntawm excavators ntawm 40 tons thiab saum toj no, "ntau yam kev khoov txoj kev" ua ke nrog cov kab nruab nrab feem ntau siv los xyuas kom meej qhov sib xws ntawm tag nrho curvature;

· Rau ultra-siab zog steel daim hlau (lub zog tensile ≥ 900MPa), yuav tsum tau ua ke cov txheej txheem ntawm segmented roller dabtsi yog khoov + hauv zos rebound kho;

· Cov phaj reinforcement nyob rau hauv boom pob ntseg ncej cheeb tsam feem ntau reserves ib co margin, thiab yog precisely positioned los ntawm machining tom qab khoov.

Cov saum toj no yog tshooj thib ob ntawm zaj yeeb yaj kiab "Lub Caij Nplooj Ntoos Hlav - Lub Yug ntawm Excavator Boom" (kom txuas ntxiv)

Post lub sij hawm: May-21-2025