Abantu abaninzi bacinga ukuba ukwenza oomatshini kukusebenza nje ngoomatshini, kwaye amalungu omatshini wokwakha osikwa ngesandla kunye neenxalenye ezingoomatshini zisebenza ngokulinganayo. Ngaba ngokwenene ziyafana? Hayi ncma. Khawufane ucinge ukuba kutheni iinxalenye zoomatshini ezenziwe eJapan naseJamani zikumgangatho ophezulu. Ukongeza kwizixhobo zomatshini eziyinkimbinkimbi, zikwaxhomekeke kwimigangatho engqongqo kunye neenkqubo. Namhlanje, masiqale ngenyathelo lokuqala: ukusika amadangatye.

1.1 Isishwankathelo seNkqubo

Ukusika idangatye linyathelo lokuqala lokulungisa imathiriyeli ekrwada kwimveliso ye-excavator boom kunye nenyathelo lokuqala ekusetyenzweni kweepleyiti koomatshini abaninzi bokwakha. Eyona njongo yayo iphambili kukwahlula ngokuchanekileyo iipleyiti ezinkulu zentsimbi zibe ngamacandelo ahlukeneyo okwenziwa okulandelayo, kubandakanywa neepleyiti zangaphandle zomqadi, iipleyiti zokuqinisa ngaphakathi, kunye neepleyiti zezitulo zetrunnion, ngokweemfuno zoyilo.

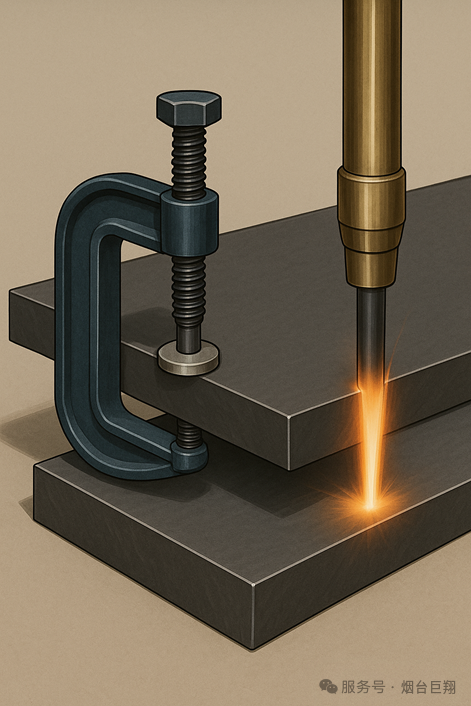

Le nkqubo isebenzisa izixhobo zokusika ze-CNC i-oxygen-fuel, eyenza ilangatye lobushushu obuphezulu usebenzisa umxube we-oxygen-acetylene ukunyibilika ngokuyinxenye kunye ne-oxidize i-carbon steel plate.

1.2 Ulungelelwaniso lweSixhobo

● Umatshini wokusika amadangatye e-CNC (i-benchtop/gantry)

● Iprogramu ezenzekelayo kunye nenkqubo yokulawula i-trajectory (esekelwe kwimizobo ye-CAD)

● Inkqubo yokubonelela nge-oksijeni kunye ne-acetylene yegesi

● Ukunyuswa kwetotshi okuzenzekelayo kunye nemodyuli yokulawula ubushushu bomlilo

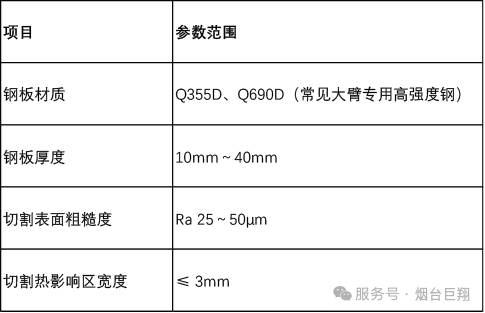

1.3 IiParamitha zeMathiriyeli

1.4 Inkqubo

1) Ukulungiselela ngaphambi kokusika

● Khangela ukuba izinto zentsimbi yentsimbi kunye nemilinganiselo iyahambelana nemizobo yoyilo;

● Susa ioli, ukufuma, nomhlwa kwindawo yentsimbi.

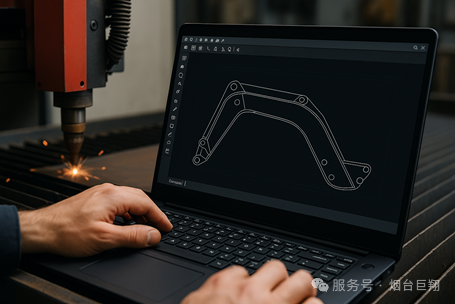

2) Ukucwangcisa nokucwangcisa

● Ngenisa uyilo lweCAD kwi-CNC cutting system;

● Yenza indlwane ekrelekrele ukuze uyisebenzise ngokupheleleyo;

● Beka umyalelo wokusika, ubeke phambili iindawo ezincinci kwiindawo ezinkulu ukukhusela ukuguqulwa kwe-thermal.

3) Ukulungiswa kwezixhobo

● Ukulungelelanisa ukuchaneka kwendlela;

● Beka uxinzelelo lwegesi yomlilo (0.4-0.6 MPa ye-oxygen, i-0.01-0.05 MPa ye-acetylene);

● Lungisa i-gap yokuqala phakathi kwetotshi yokusika kunye nesitya sensimbi (3-5 mm).

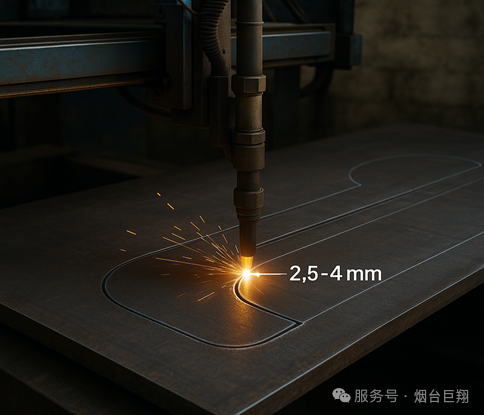

4) Ukubulawa kweFlame cut

● I-ignition ifudumeza ukuya kwindawo yokutshisa;

● Intloko yokusika ihamba ngokuzenzekelayo kwi-trajectory, ngelixa ukusika amadangatye kuqhubeka ngaxeshanye;

● Igcina ububanzi bekerf obuzinzile (budla ngokuba yi-2.5mm ukuya kwi-4mm) ukunqanda ukutsha okungalinganiyo.

5) Ukuhlolwa komgangatho

● Jonga ngokubonakalayo ukuma okusikiweyo kunye nokucoceka komphezulu;

● Sebenzisa i-ultrasonic gauge ukuqinisekisa ubunzulu bendawo echatshazelwe bubushushu kwiindawo eziphambili;

● Khangela ukunyamezela kwe-dimensional of the cut parts (ngokubanzi ≤± 1.5mm).

6) Emva kokulungiswa

● Zisuse ngesandla iibhula zokusika;

● Coca isikali seoxide ukuthintela imingxunya ye-welding elandelayo.

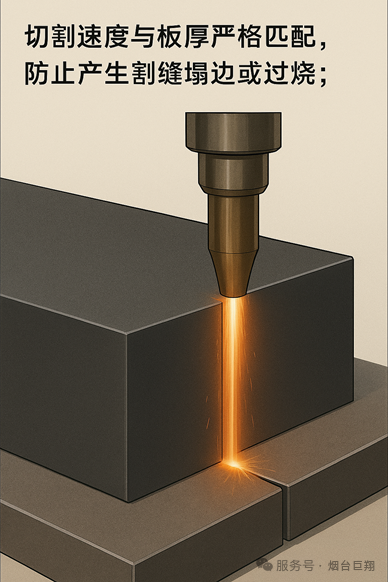

1.5 Amanqaku oBuchule kunye nokuQapha

● Isantya sokusika sihambelana ngokungqongqo kunye nobukhulu beplate ukukhusela umgca wokusika ekuweni okanye ukutshisa;

● Ipleyiti yentsimbi kufuneka ibotshwe ngokuzinzileyo ukuphepha ukungcangcazela ngexesha lokusika okunokubangela ukutenxa kwindlela yokusika.

● Kwiipleyiti ezishinyeneyo ezingaphezulu kwe-40mm, isicwangciso-qhinga sokufudumeza umlilo esinamanqanaba amaninzi kufuneka sisetyenziswe ukuphucula ubume be-kerf.

● Gcina ukucoceka kwe-oksijeni ye-≥99.5%, ngaphandle koko ukuguquguquka kwendawo yokusika kuya kuchaphazeleka.

● Ngexesha lokuvelisa, utshintsho lobushushu bomlilo kufuneka lubekwe esweni ngexesha langempela ukulungisa umlinganiselo wegesi ngokukhawuleza.

Oku ngasentla linyathelo lokuqala kwi-machining of excavators oomatshini bokwakha, ukusika amadangatye.

Ixesha lokuposa: Jul-31-2025