Kwinkqubo yokwenziwa kwengalo yomemba, "iplate leveling and beveling" yinkqubo esisiseko ebaluleke kakhulu kuyo yonke inkqubo. Nangona kungelona khonkco libonakalayo, kufana nonyango lwesiseko ngaphambi kokwakha indlu, emisela ukuba i-welding elandelayo, indibano, kunye nokuchaneka komdaniso kunokuba "i-smoothly on track".

Namhlanje siza kuthetha ngento eyenziwa leli nyathelo, indlela yokwenza, kwaye kutheni ingenakugcinwa.

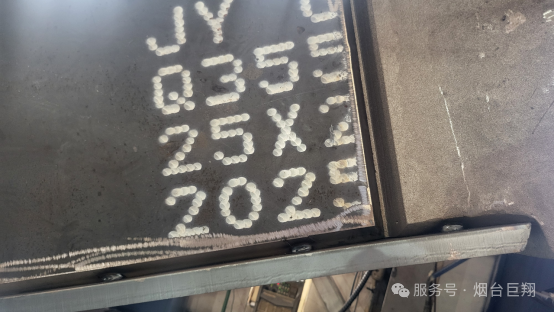

3.1 Kutheni le nto ukulinganisa kuyimfuneko?

Kutheni le nto kufuneka "inqanaba"? Ngaba ipleyiti yentsimbi ayicaba emva kokusikwa?

Eneneni, akunjalo.

Emva kokusikwa kwedangatye okanye iplasma, ipleyiti yentsimbi iya kuba noguquko olucacileyo lwamaza, uxinzelelo lwe-thermal warping okanye ukugqwetheka kwekona. Ezi ziphene zibonakala zincinci, kwi-excavator boom, ingalo yolwandiso, ingalo yokuqhubela imfumba kunye nezinye iindawo eziziimitha ezingaphezulu kweemitha ezili-10 ubude kwaye zithwele iitoni ezininzi zobunzima, nokuba ukutenxa nge-2 mm kunokubangela:

· Weld umthungo "misalignment" kunye undercut;

· Indibano elandelayo ayihambelani nomngxuma;

· Ukugxininiswa koxinzelelo olushiyekileyo emva kwe-welding, nokuba "kukuqhekeka" emva kweminyaka embalwa yokusetyenziswa.

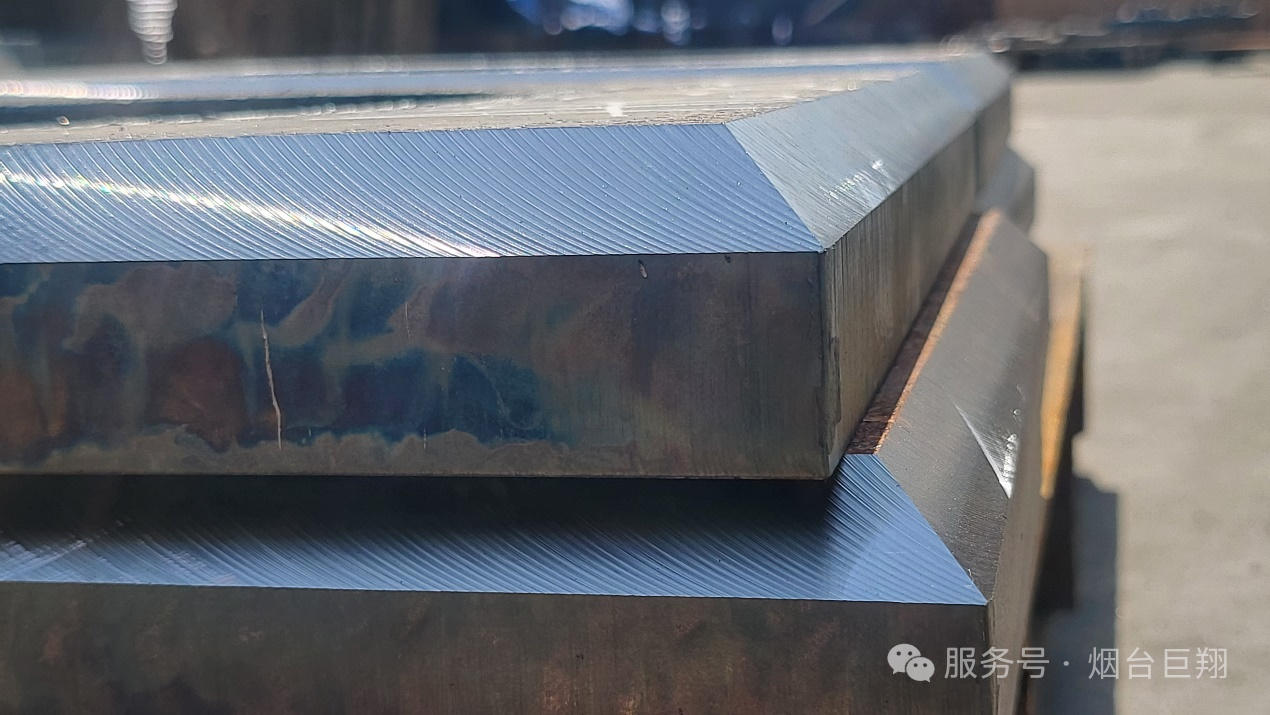

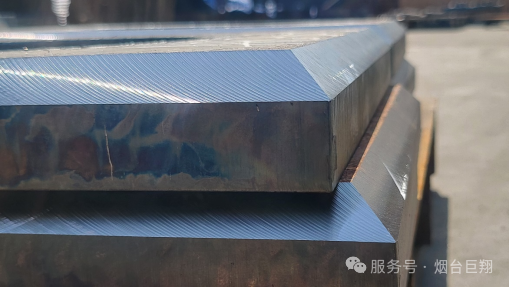

Ngoko ke, ipleyiti yensimbi kufuneka igxininiswe ngokuphindaphindiweyo usebenzisa umatshini wokulinganisa kunye neeseti ezininzi ze-roller eziphezulu kunye nezantsi ukuphelisa uxinzelelo lwangaphakathi kunye nokubuyisela i-flatness.

Amanqaku aphambili omgangatho:

· I-flatness yentsimbi yentsimbi kufuneka ilawulwe ngaphakathi kwe-± 2mm / m;

· Amacala omabini epleyiti yentsimbi kufuneka acinezelwe ngaxeshanye ukuphepha ukuguqula umva;

· Kwiipleyiti zetsimbi ezityebileyo (> 20mm), kuyimfuneko ukulinganisa ngokuphindaphindiweyo kumacandelo, kwaye akunakwenzeka ukuba "ucinezele yonke indlela ukuya ezantsi kwindlela enye".

3.2 Yintoni “ukuvula ithambeka”?

Yintoni "ukuhlambalaza"? Kutheni le nto kufuneka siwubethelele umphetho wepleyiti?

Ukubeka ngokulula: ukwenza i-weld yomelele.

Iipleyiti zentsimbi eziqhelekileyo zinemiphetho ethe tye. Ukuba i-butt i-welded ngokuthe ngqo, ubunzulu bokungena akwanelanga kwaye i-weld ayizinzanga. Ngaphezu koko, isinyithi asinakuxutywa ngokupheleleyo, nto leyo ekhokelela ngokulula kwiziphene ze-welding ezifana ne-welding ebandayo, i-slag inclusions, kunye ne-pores.

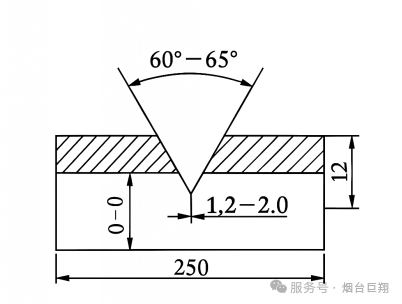

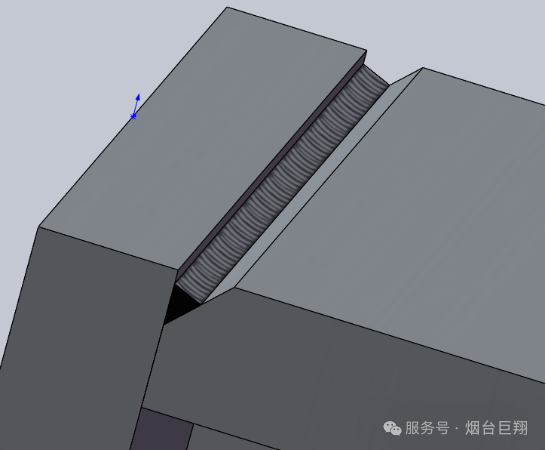

Ngoko ke, umgca weplate kufuneka uqhutywe kwi-V-shaped, i-X-shaped okanye i-U-shaped notch ukwenzela ukuba intonga ye-welding okanye ucingo lukwazi ukungena phantsi kwaye "lulume" iiplate ezimbini.

Iifom zegroove eziqhelekileyo:

Icala elinye elinemilo engu-V licala lithambekele, lisebenza kubukhulu obungaphantsi okanye obulingana ne-20mm; amacala amabini amile okwe-X anamacala amabini athambekele ngokulinganayo, asebenzayo kubukhulu obuyi-20-40mm; Ubume be-K kunye no-U busebenza kwiipleyiti ezityebileyo ezongezelelweyo, ubukhulu obungaphezulu okanye obulingana ne-40mm.

Ulawulo ngokubanzi lweparameters zegroove:

· I-engile: 30 ° ~ 45 ° kwelinye icala, i-engile symmetrical ayidluli kuma-65 °

· Ungqameko olubuthuntu: 2 ~ 4mm

· “Ukudilika kwekona”, “ukukrazuka komphetho” kunye “nokutshisa” akuvumelekanga

Iindlela zokulungisa:

· Ibhetshi yomphetho wepleyiti ethe tye → umatshini wokusika i-CNC idangatye/iplasma beveling

· Amalungu asekuhlaleni amile okwexesha elithile → i-carbon arc gouging + ukucola

· Ukuchaneka okuphezulu → umatshini wokusila we-CNC / ukusika i-robot beveling

3.3 Inkqubo ye-beveling enengqiqo

Inkqubo ye-groove efanelekileyo kukulungiselela i-welding multi-layer enengqiqo kunye nokwandisa umthamo we-solder kunye nenani leengqimba ze-weld. Kuya kwenzeka ntoni ukuba eli nyathelo alenziwanga kakuhle?

· I-welding deformation enkulu: I-shrinkage force ye weld iya "kutsala yonke into egoso"

· Indibano enzima: Isikhundla somngxuma asihambelani, kwaye umdibaniso awukwazi ukufakwa

· Ukudinwa kukuqhekeka: Uxinzelelo olushiyekileyo + iziphene zokuwelda, ukwaphuka kwesakhiwo kwiminyaka embalwa

· Ukunyuka kweendleko: Ukuphinda usebenze, ukugaya, ukuphinda usebenze, okanye ukukrazula ingalo yonke

Ngoko ke, kudla ngokuthiwa kwishishini: "Ukuba ipleyiti ayilungiswanga kwaye i-groove ayenziwa kakuhle, kungakhathaliseki ukuba i-welder ilungile kangakanani, ayiyi kuba luncedo."

Kwisivakalisi esinye:

"I-Plate leveling + beveling" linyathelo lokuqala lokuphucula umgangatho we-welding kunye nesiqalo se-boom ukusuka "kukwazi ukuwelda" ukuya "ku-welding stably".

Isenokungabi yintlekisa, kodwa ngaphandle kwayo, konke ukuchaneka, ukomelela nokhuseleko olulandelayo kuya kuba yintetho nje engenamsebenzi.

Ixesha lokuposa: Jun-12-2025