Me yasa wasu samfuran injina ke da manyan wuraren bawon fenti da tsatsa bayan dogon lokaci, yayin da wasu samfuran na iya zama masu ɗorewa? A yau, bari muyi magana game da matakan da suka dace don fenti mai inganci kafin ginin fenti - cire tsatsa !!!

1. Me yasa muke buƙatar yin wannan matakin don fenti mai inganci akan injinan duniya?

· Cire tsatsa, cire walda, da cire tsohon fenti

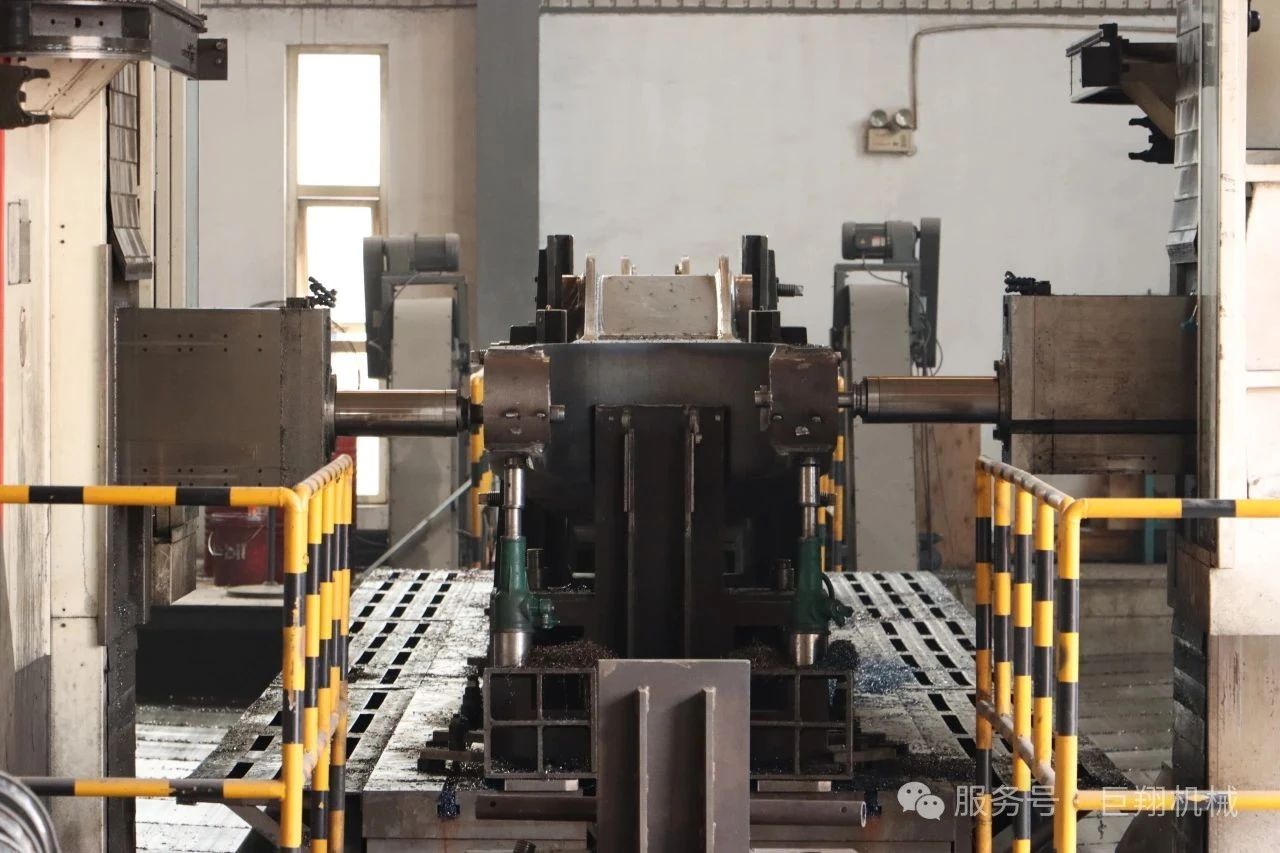

Bayan waldi da sarrafa, da albarku sau da yawa yana da tsatsa spots, sikelin, waldi slag, da dai sauransu. Nika na yau da kullun ba shi da inganci kuma ba za a iya cire shi gaba ɗaya ba. Sandblasting zai iya kawar da duk gurbatar yanayi yadda ya kamata kuma ya dawo da haske mai haske.

· Aikin farko na saman

Karamin madaidaicin wuri da madaidaicin saman da yashi ya bari yana samar da “madaidaicin mannewa” don sanya madaidaicin na gaba ya zama mai ƙarfi kuma baya sauƙin faɗuwa.

· Rage damuwa na ciki

Babban tasiri na sauri zai iya sakin wasu damuwa na saura bayan waldi kuma ya rage haɗarin fashewar gajiya.

2. Me za a yi fashewa? Jagoran Zaɓin Mai jarida

Kafofin watsa labaru gama gari sun haɗa da:

Karfe yashi/harbin karfe: cire tsatsa mai nauyi mai nauyi, ingantaccen inganci, amma buƙatun kayan aiki masu girma (sake yin amfani da su da sarrafa manyan kafofin watsa labarai).

· Gilashin gilashi / yashi aluminum / yashi zirconium / garnet: matsakaicin ƙarfi, mai sauƙin sarrafa sakamako na farko.

* Kafofin watsa labarai na filastik ko na halitta (kamar bawowar goro, ƙwanƙolin masara): tsaftacewa mai laushi, babu lahani ga ma'auni, dacewa da cikakkun bayanai ko sassa nakasu cikin sauƙi.

3. Dry spraying vs. rigar spraying: zabi wanda ya dace don kwanciyar hankali

Dry spraying (Fa'idodin: saurin kawar da tsatsa, ƙarancin farashi, babban inganci; Rashin amfani da iyakancewa: babban ƙurar tashi, buƙatar kula da kariyar muhalli da samun iska.)

Rigar da ake amfani da shi (Amfani: raguwar ƙura a fili, rage raunin yashi mai tashi da tsangwama a tsaye; Rashin lahani da iyakancewa: hadaddun kayan aiki, ɗan ƙaramin farashi, maganin ruwa yana buƙatar ƙarin la'akari.)

Ana amfani da busassun bushewa a cikin masana'antun haɓaka, wanda ke da inganci da sauri; amma idan akwai buƙatu don kula da muhalli da ƙura, ko a lokacin damina/rufe muhalli, fesa rigar shine madadin da ya dace.

4. Tsarin yashi, babu wani mataki da aka rasa

1) Kariyar garkuwa

Aiwatar da tef ko allo na kariya don kare sassan da ba a fesa ba, kamar musaya na ruwa da zoben rufewa.

2) Dakin fesa yana cikin wurin kuma yana da iska sosai

Yi amfani da dakin feshi ko buɗaɗɗen wurin aiki don tabbatar da cewa ƙura ta tsotse cikin lokaci.

3) Saita sigogi

Daidaita matsa lamba zuwa 90-100 psi (kimanin sanduna 6-7), kuma ajiye bindigar fesa kamar 10-15cm a tsaye zuwa saman.

4) Matakin fesa

Shafa a ko'ina da sannu a hankali, a hankali a rufe, kuma a magance sauƙin tara ƙura da kusurwoyin matattu; Yashi barbashi tasiri da kuma bawo kashe gurbataccen Layer a babban gudun.

5) Yashi dawo

Yawancin su tsarin rufaffiyar kewayawa ne, tace kura da sake amfani da kafofin watsa labarai don rage sharar gida.

6) Tsaftace kura

Bayan an fesa, yi amfani da matsewar iska ko cire ƙura don tabbatar da tsaftataccen wuri.

5. Yawancin fa'idodin tsarin

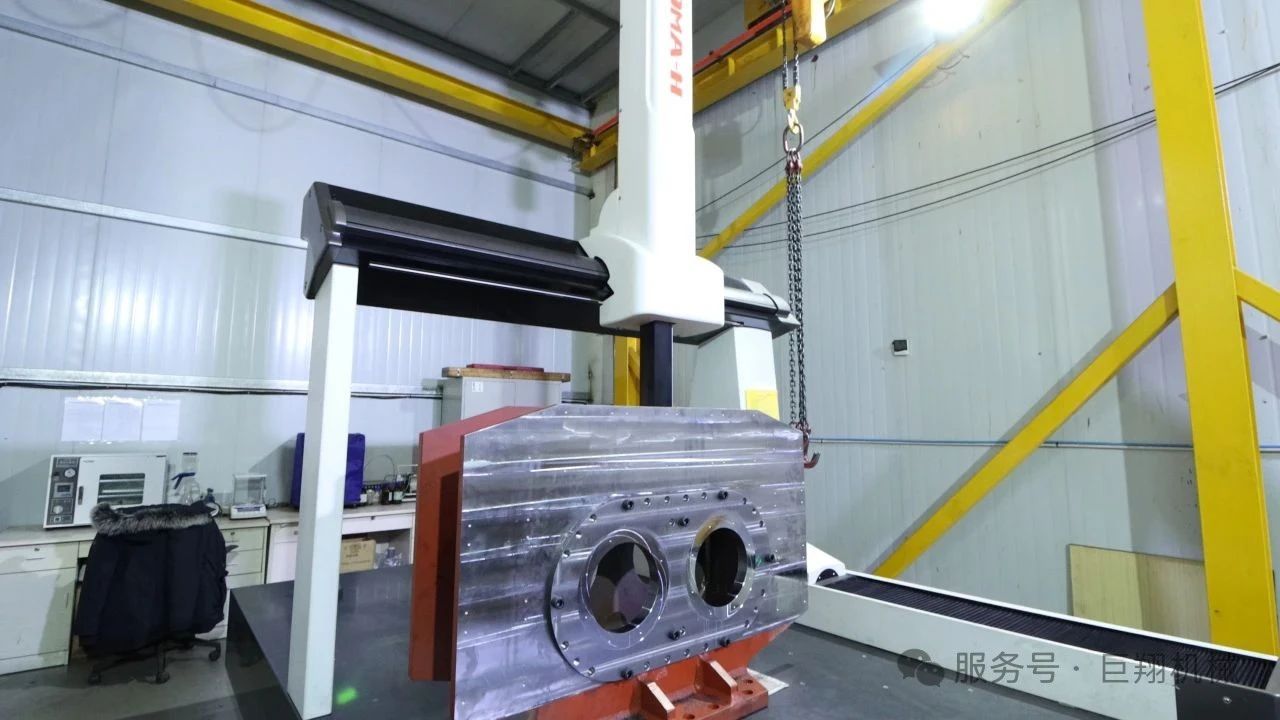

Ƙwarewar ban mamaki: za a iya dawo da asalin launi na karfe a cikin 'yan mintoci kaɗan, kuma ana iya tsaftace walda da tsatsa da sauri;

· Rufe mai tsayi mai tsayi: ƙasa mai laushi yana inganta juriya ga kwasfa kuma an inganta ƙarfin fenti sosai;

· Mai sauƙin kulawa: sauƙin gudanarwa bayan yashi da haɓaka juriya na lalata;

· Ƙwararrun masana'antu: bayan fashewar yashi, an gabatar da nau'in nau'i na "matte", wanda yake duka biyu da na gani.

6. Nasihun Tsaro

Sandblasting yana da kyau, amma kuma yana da haɗarin ɓoye:

Ma'aikata suna buƙatar sanya abin rufe fuska mai jure matsi, kariya ta ji, da safar hannu masu nauyi

· Yi amfani da kafofin watsa labarai marasa guba don guje wa hatsarori na sana'a

Dole ne a ware muhallin da ke da ƙurar ƙura, da hana wuta, da kuma hana fashewa

Sauya nozzles akai-akai: lalacewa da tsagewa zai rage aiki da haifar da ɓarnawar yashi

Yashi da niƙa da hannu ba sa gaba da juna. Madadin haka, ƙarin amfani na iya inganta inganci

Shawarwari masu dacewa

· Matakin sarrafawa: da farko a yi amfani da niƙa na hannu don aiwatar da wuraren waldawa da ɓangarorin gefuna.

· Matakin sarrafa batch: Ana amfani da fashewar yashi don manyan wurare, wanda yake da inganci kuma yana da kyau adhesion.

Matsayi mai kyau: daidaitawa da sake niƙa ƙananan lahani, kuma a ƙarshe sarrafa ƙura da tsaftace saman.

| Hanya | Amfani | Rashin amfani |

| Manual nika (sanda / niƙa dabaran / kwana grinder) | 1) Ƙananan farashi da kayan aiki masu sauƙi 2) Ya dace da daidaitattun gyaran gida 3) Karancin ƙura da sauƙin sarrafawa | 1) Ƙananan inganci don manyan wurare 2) Mai ɗaukar lokaci da aiki mai ƙarfi, aiki tuƙuru 3) Rashin daidaituwar yanayi yana shafar mannewar fim ɗin fenti |

| Tashin iska mai bushewa (bushewar iska mai ƙarfi) | 1) Babban inganci, zai iya aiwatar da manyan yankuna da sauri 2) Taushin sararin sama bai dace ba, har zuwa matakin micron 3) Kyakkyawan aiki daki-daki, welds da matattu sasanninta za a iya tsabtace 4) Rage danniya da inganta m shafi mannewa | 1) Babban zuba jari na kayan aiki na farko 2) Busassun fesa yana haifar da ƙura mai yawa kuma yana buƙatar sarrafa ƙura 3) Rigar spraying yana jinkirin, yana da buƙatun muhalli masu yawa, da hadadden maganin yashi |

| Injiniyan harbi ta atomatik mai fashewa / fashewar yashi | 1) Babban aiki da kai, daidaito mai kyau, ƙarancin dogaro da hannu 2) Ikon sarrafawa da yawa akai-akai ba tare da gajiyawar hannu ba | 1) Kayan aiki yana da girma da tsada 2) Maiyuwa baya cika hadaddun/manyan sifofi 3) Yana da ƙarancin sassauci kuma bai dace da ayyuka na wucin gadi ko ƙananan ayyuka ba |

Ga hannun haƙa, ɓarkewar yashi yana da inganci sosai, mai inganci kuma mai jure lalata. Babban abu shine: fesa wuraren tsatsa + ƙirƙirar ƙasa mara kyau + haɓaka fenti, haɓaka ta bushewa / rigar fesa, zaɓi matsakaicin matsakaici da kariyar aminci. Tsarin yana da ban mamaki.

Wannan matakin yana haɓaka inganci da dorewa na gabaɗayan aikin simintin gyare-gyare/ƙera. Idan kuna son ƙarin sani game da ƙirar kayan aikin yashi, bidiyon gini ko farashin kayan, kuna iya ci gaba da yin taɗi!

Lokacin aikawa: Jul-02-2025