A cikin aikin kera na hannun haƙa, "daidaita farantin karfe da beveling" wani muhimmin tsari ne na asali a cikin gaba ɗaya tsari. Ko da yake ba shine mafi kyawun hanyar haɗin yanar gizon ba, yana kama da jiyya na tushe kafin gina gida, wanda ke ƙayyade ko walda, taro, da daidaito na gaba na iya zama "lafiya akan hanya".

Yau za mu yi magana game da abin da wannan mataki yake yi, yadda za a yi shi, da kuma dalilin da ya sa ba zai iya samun ceto ba.

3.1 Me yasa matakin ya zama dole?

Me ya sa muke bukatar mu "mataki"? Ashe farantin karfen baya lebur bayan yankan?

A gaskiya, ba haka ba ne.

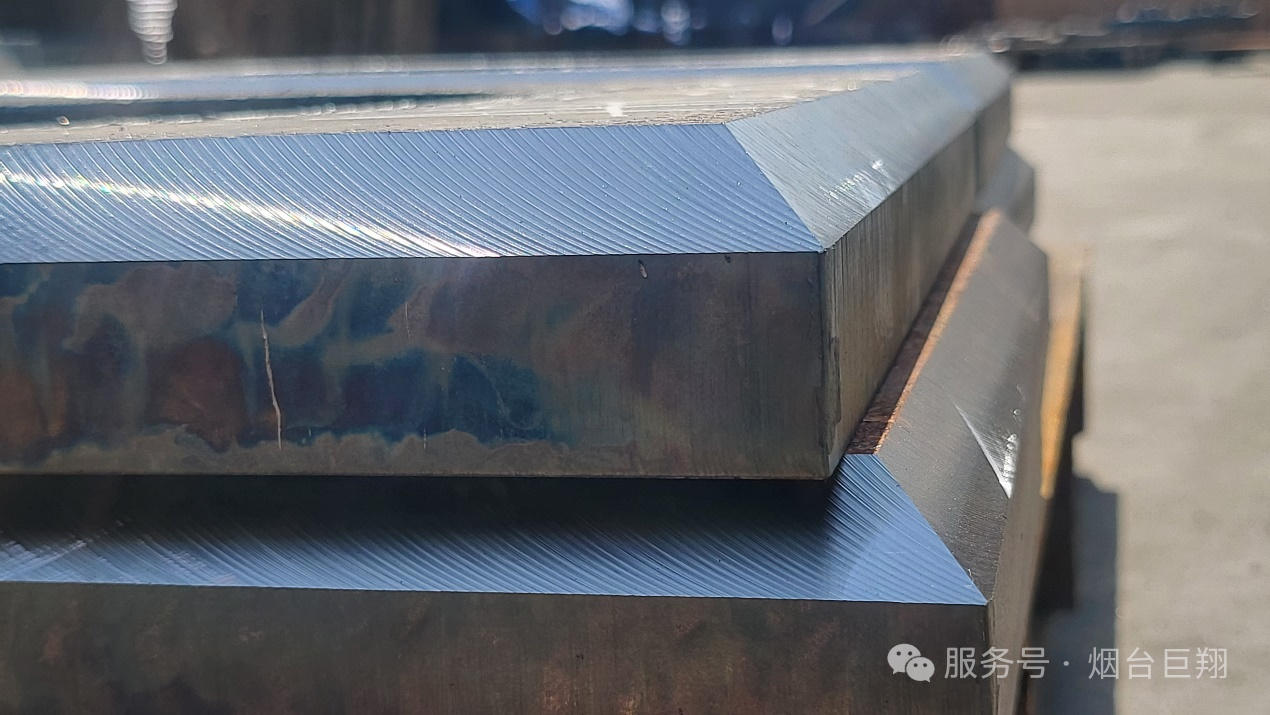

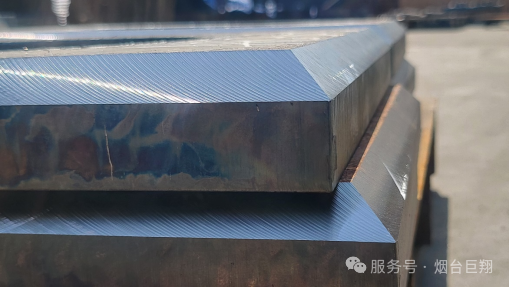

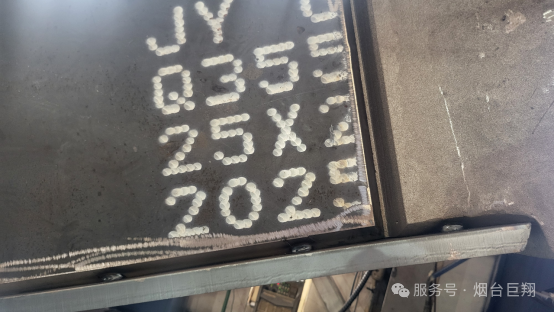

Bayan yankan harshen wuta ko plasma, farantin karfen zai sami nakasar raƙuman ruwa, zafi mai zafi ko murdiya. Waɗannan ƙananan nakasassu, a cikin haɓakar haɓakar hakowa, hannu mai tsawo, hannun tuƙi da sauran sassan tsarin da suka fi tsayin mita 10 kuma suna ɗaukar nauyin ton da yawa, ko da karkacewar 2 mm na iya haifar da:

· Weld dinki "misalignment" da kuma karkashin yanke;

· Taron na gaba bai dace da ramin ba;

· Rage yawan damuwa bayan waldawa, har ma da "fashewa" bayan 'yan shekaru na amfani.

Sabili da haka, dole ne a danna farantin karfe akai-akai ta amfani da na'ura mai daidaitawa da nau'i-nau'i masu yawa na manya da ƙananan rollers don kawar da damuwa na ciki da mayar da hankali.

Mahimman abubuwan daidaitawa:

· Ya kamata a sarrafa nauyin farantin karfe a cikin ± 2mm / m;

· Ya kamata a danna ɓangarorin biyu na farantin karfe a lokaci guda don guje wa juyawa baya;

Don faranti masu kauri (> 20mm), ya zama dole a daidaita su akai-akai a cikin sassan, kuma ba zai yiwu a "danna su ba har zuwa ƙasa a tafi ɗaya".

3.2 Menene "buɗe gangara"?

Menene "beveling"? Me yasa muke buƙatar karkatar da gefen farantin?

A sauƙaƙe: don ƙara ƙarfin walda.

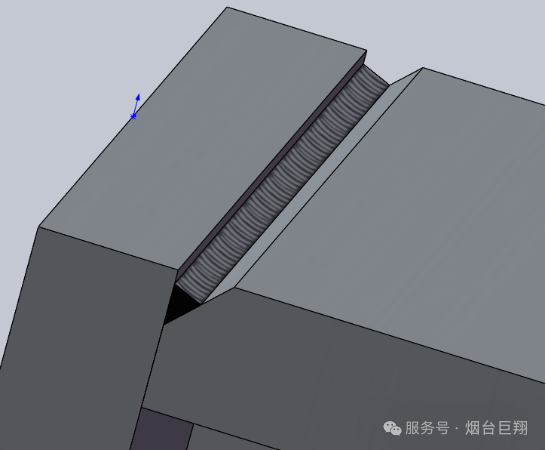

Farantin karfe na yau da kullun suna da gefuna madaidaiciya. Idan sun kasance kai tsaye butt welded, shigar azzakari cikin farji bai isa ba kuma weld ne m. Bugu da ƙari, ba za a iya haɗakar da ƙarfe gabaɗaya ba, wanda cikin sauƙi yana haifar da lahani na walda kamar walda mai sanyi, haɗaɗɗen slag, da pores.

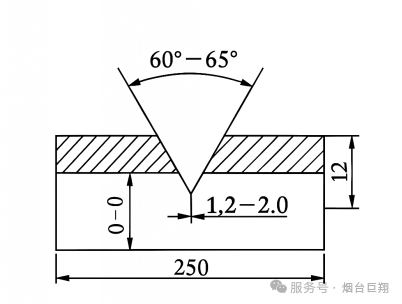

Don haka, ya kamata a sarrafa gefen farantin zuwa wani nau'i na V-dimbin yawa, X-dimbin yawa ko U-dimbin yawa domin sandar walda ko waya za ta iya shiga ƙasa kuma ta "ciji" gefuna biyu na farantin.

Siffofin tsagi gama gari:

Siffar V mai gefe guda ɗaya tana karkata gefe ɗaya, wanda ya dace da kauri ƙasa da ko daidai da 20mm; Siffar X mai gefe biyu tana da madaidaicin ɓangarorin biyu, wanda ya dace da kauri 20-40mm; Siffar K da U-dimbin yawa ana amfani da su zuwa ƙarin faranti masu kauri, kauri fiye da ko daidai da 40mm.

Gabaɗaya sarrafa sigogin tsagi:

Angle: 30° ~ 45° a gefe ɗaya, kusurwar simmetric ba ta wuce 65°

Ƙaƙƙarfan baki: 2 ~ 4mm

Ba a yarda da "Rushewar kusurwa", "yaga gefuna" da "ƙonawa" ba

Hanyoyin sarrafawa:

· Batch madaidaiciya farantin gefe → CNC harshen wuta / Plasma beveling inji

· Sassan gida na musamman masu siffa → guguwar carbon arc + niƙa

· Babban madaidaicin → CNC milling machine / robot beveling yankan

3.3 Tsarin beveling mai ma'ana

A m tsagi tsari shi ne a shirya don m Multi-Layer waldi da kuma ƙara solder iya aiki da adadin yadudduka ga weld. Menene zai faru idan ba a yi wannan matakin da kyau ba?

Babban nakasar walda: Ƙarfin ƙullewar walda zai “jawo dukkan abubuwan da suka karkace”

Haɗuwa mai wahala: Matsayin ramin baya daidaitacce, kuma ba za a iya shigar da mai haɗawa ba

· Fatsin gajiya: Rage damuwa + lahani na walda, karyewar tsari a cikin ƴan shekaru.

Haɓaka farashi: Sake yin aiki, niƙa, sake yin aiki, ko ma goge gaba ɗaya hannu

Don haka, ana yawan cewa a cikin masana’antar: “Idan ba a daidaita faranti ba kuma ba a yi tsagi da kyau ba, komai kyawun walda, ba shi da amfani.”

A cikin jumla guda:

"Plate Leveling + beveling" shine mataki na farko don inganta ingancin walda da kuma wurin farawa ga bunƙasa don tafiya daga "welding m" zuwa "welding stably".

Yana iya zama ba abin ban sha'awa ba, amma idan ba tare da shi ba, duk daidaito, ƙarfi, da aminci na gaba za su zama zancen banza.

Lokacin aikawa: Juni-12-2025