Enqubweni yokukhiqiza ingalo yomgodi, "ukulinganisa amapuleti kanye ne-beveling" kuyinqubo eyisisekelo ebaluleke kakhulu kuyo yonke inqubo. Nakuba kungesona isixhumanisi esigqama kakhulu, kufana nokwelashwa kwesisekelo ngaphambi kokwakha indlu, okunquma ukuthi ukushisela okulandelayo, ukuhlanganisa, nokunemba kobukhulu kungase "kuhambe kahle ngokushelelayo".

Namuhla sizokhuluma ngokuthi lesi sinyathelo senzani, kanjani, nokuthi kungani singeke sisindiswe.

3.1 Kungani kudingeka ukulinganisa?

Kungani sidinga “izinga”? Ingabe ipuleti lensimbi alisicaba ngemva kokusika?

Empeleni, akunjalo.

Ngemuva kokusika ilangabi noma i-plasma, ipuleti lensimbi lizoba nokuguquguquka okusobala kwegagasi, i-thermal stress warping noma ukuhlanekezela ekhoneni. Lokhu kuguga okubonakala kuncane, ku-excavator boom, ingalo yokwelulwa, ingalo yokushayela inqwaba nezinye izingxenye zesakhiwo ezingaphezu kwamamitha ayi-10 ubude futhi zinesisindo esingamathani amaningana, ngisho nokuchezuka okungu-2 mm kungase kubangele:

· Weld umthungo “ukungasebenzi kahle” kanye ne-undercut;

· Ukuhlanganiswa okulandelayo akufani nomgodi;

· Ukugxiliswa kwengcindezi eyinsalela ngemva kokushisela, ngisho “nokuqhekeka” ngemva kweminyaka embalwa yokusetshenziswa.

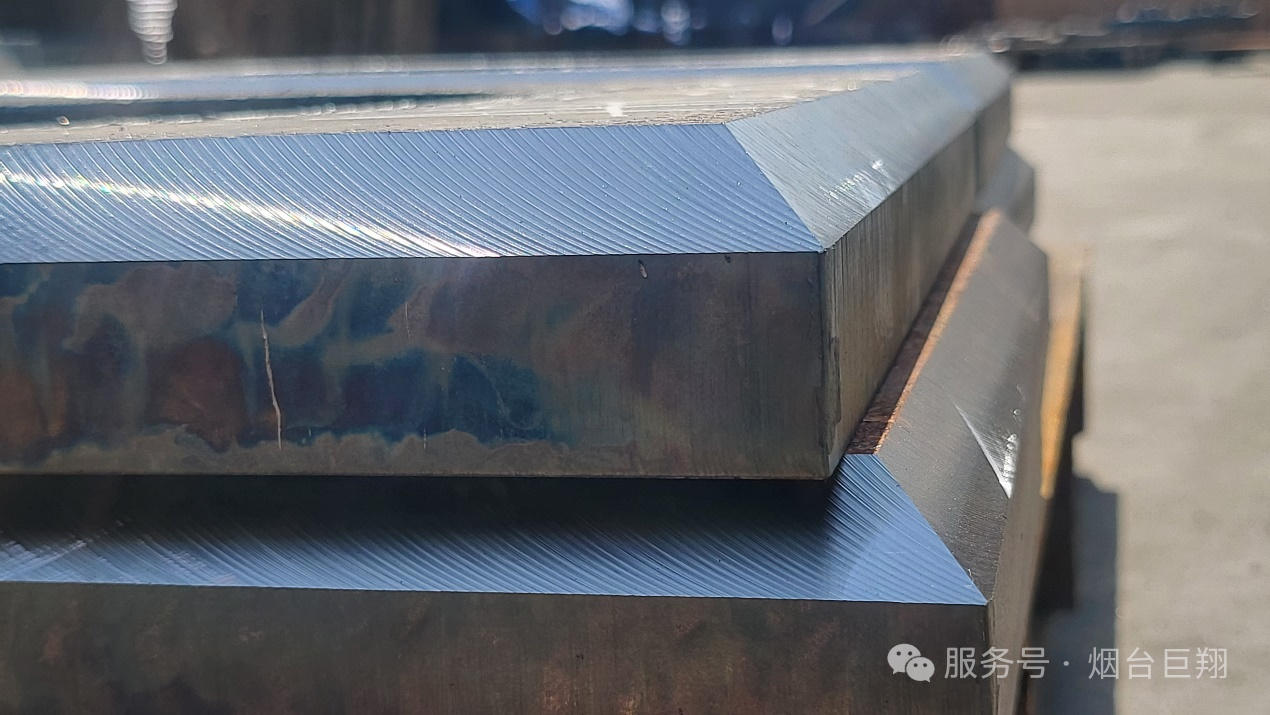

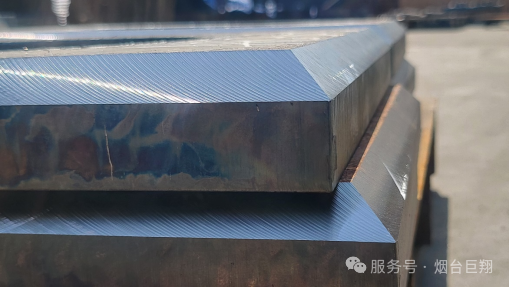

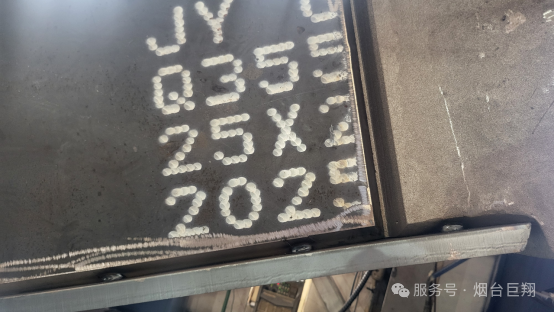

Ngakho-ke, ipuleti yensimbi kufanele icindezelwe ngokuphindaphindiwe kusetshenziswa umshini wokulinganisa kanye namasethi amaningi ama-roller aphezulu naphansi ukuze kuqedwe ukucindezeleka kwangaphakathi nokubuyisela flatness.

Amaphuzu angukhiye wokulinganisa:

· Ukucaba kwepuleti lensimbi kufanele kulawulwe ku-±2mm/m;

· Zombili izinhlangothi zensimbi kufanele zicindezelwe ngesikhathi esisodwa ukuze kugwenywe ukuhlehla kokuhlehla;

· Kumapuleti ensimbi aminyene (>20mm), kuyadingeka ukuwalinganisa ngokuphindaphindiwe ezigabeni, futhi akunakwenzeka “ukuwacindezela aze afike phansi ngesikhathi esisodwa”.

3.2 Kuyini “ukuvuleka komthambeka”?

Kusho ukuthini "i-beveling"? Kungani sidinga ukugoba umphetho wepuleti?

Kalula nje: ukwenza i-weld ibe namandla.

Amapuleti ensimbi avamile anemiphetho eqondile. Uma i-butt eshiselwe ngokuqondile, ukujula kokungena akwanele futhi i-weld ayizinzile. Ngaphezu kwalokho, insimbi ayikwazi ukuhlanganiswa ngokugcwele, okuholela kalula ekushiseni okufana nokushisela okubandayo, ukufakwa kwe-slag, nama-pores.

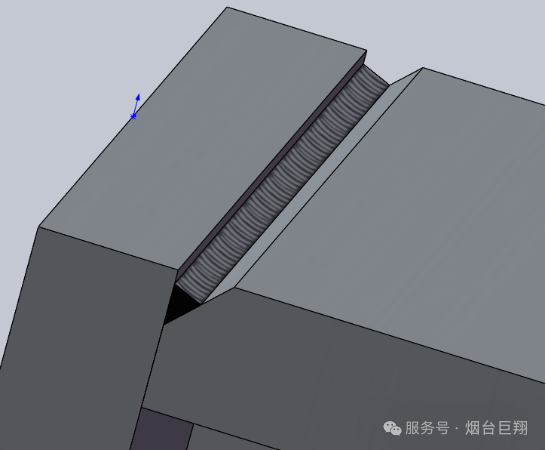

Ngakho-ke, unqenqema lwepuleti kufanele lucutshungulwe lube yinothi emise okwe-V, emise okwe-X noma emise okwe-U ukuze induku yokushisela noma ucingo lungene phansi futhi "lulume" emaphethelweni amapuleti amabili.

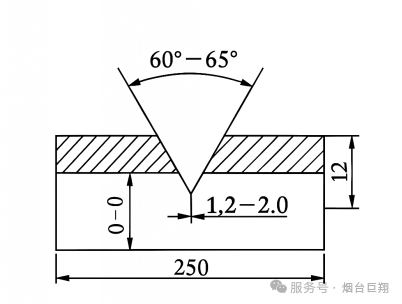

Amafomu e-groove ajwayelekile:

Uhlangothi olulodwa olumise okwe-V luhlangothi olulodwa oluthambekele, lusebenza kugqinsi olungaphansi noma olulingana no-20mm; ezinhlangothini ezimbili ezimise okuka-X yizinhlangothi ezimbili ezithambekele ngokulinganayo, ezisebenza kugqinsi 20-40mm; Okumise okwe-K nokumise okwe-U kuyasebenza kumapuleti awugqinsi engeziwe, ugqinsi olukhulu noma olulingana no-40mm.

Ukulawulwa okujwayelekile kwamapharamitha we-groove:

· I-engeli: 30°~45° ohlangothini olulodwa, i-engeli yokulinganisa ingeqi ku-65°

Unqenqema olubuthuntu: 2 ~ 4mm

· “Ukugoqa kwekhona”, “ukuklebhuka komphetho” kanye “nokushiswa” akuvunyelwe

Izindlela zokucubungula:

· Iqoqo eliqondile lepuleti onqenqemeni → CNC ilangabi/plasma beveling umshini wokusika

· Izingxenye zendawo ezimise okukhethekile → i-carbon arc gouging + ukugaya

· Ukunemba okuphezulu → umshini wokugaya we-CNC/i-robot beveling cutting

3.3 Inqubo ye-beveling enengqondo

Inqubo ye-groove enengqondo ukulungiselela ukushisela okunezingqimba eziningi okunengqondo nokwandisa umthamo we-solder kanye nenani lezendlalelo ze-weld. Kuzokwenzekani uma lesi sinyathelo singenziwa kahle?

· I-welding deformation enkulu: Amandla okuncipha we-weld “azodonsa yonke ingxenye egwegwile”

· Umhlangano onzima: Indawo yembobo ayiqondile, futhi isixhumi asikwazi ukufakwa

· Ukuqhekeka kokukhathala: Ingcindezi eyinsalela + amaphutha okushisela, ukuphuka kwesakhiwo phakathi neminyaka embalwa

· Ukwenyuka kwezindleko: Sebenza kabusha, ukugaya, sebenza kabusha, noma ukuklwebha ingalo yonke

Ngakho-ke, ngokuvamile kuthiwa embonini: "Uma ipuleti lingalingani futhi i-groove ingenziwanga kahle, kungakhathaliseki ukuthi i-welder inhle kangakanani, ngeke isebenze."

Ngomusho owodwa:

I-"Plate leveling + beveling" isinyathelo sokuqala sokuthuthukisa ikhwalithi yokushisela kanye nendawo yokuqala yokuthi i-boom isuke “kukwazi ukushisela” iye “kuwelding ngokuzinzile”.

Ingase ingabi bukhazikhazi, kodwa ngaphandle kwayo, konke ukunemba okulandelayo, amandla, nokuphepha kuyoba inkulumo eyize.

Isikhathi sokuthumela: Jun-12-2025