Mukugadzira nzira yeruoko rwekuchera, "plate leveling uye beveling" idanho rakanyanya kukosha mukuita kwese. Kunyangwe isiri iyo inonyanya kuoneka chinongedzo, yakafanana nekurapa kwehwaro usati wavaka imba, iyo inosarudza kana iyo inotevera welding, gungano, uye dimensional kurongeka kunogona "kupfava mugwara".

Nhasi tichataura pamusoro pezviri kuitwa nedanho iri, kuti roitwa sei, uye nei risingagoni kuponeswa.

3.1 Sei kuenzana kuchidikanwa?

Nei tichifanira “kudzikamisa”? Handiti ndiro yesimbi haina kufuratira mushure mekucheka?

Chaizvoizvo, hazvisi.

Mushure mekucheka kwemurazvo kana plasma, ndiro yesimbi ichave neyakajeka wave deformation, thermal stress warping kana kona kukanganisa. Izvi zvinoita kunge zvidiki deformation, mune yekuchera boom, ruoko rwekuwedzera, ruoko rwekutyaira murwi uye zvimwe zvikamu zvechimiro zvinodarika mamita gumi kureba uye zvinotakura matani akati wandei ekurema, kunyangwe kutsauka kwe2 mm kunogona kukonzera:

· Weld musono "misalignment" uye undercut;

· Kusangana kunotevera hakuenderane negomba;

· Residual stress concentration after welding, even “cracks” after a few years of use.

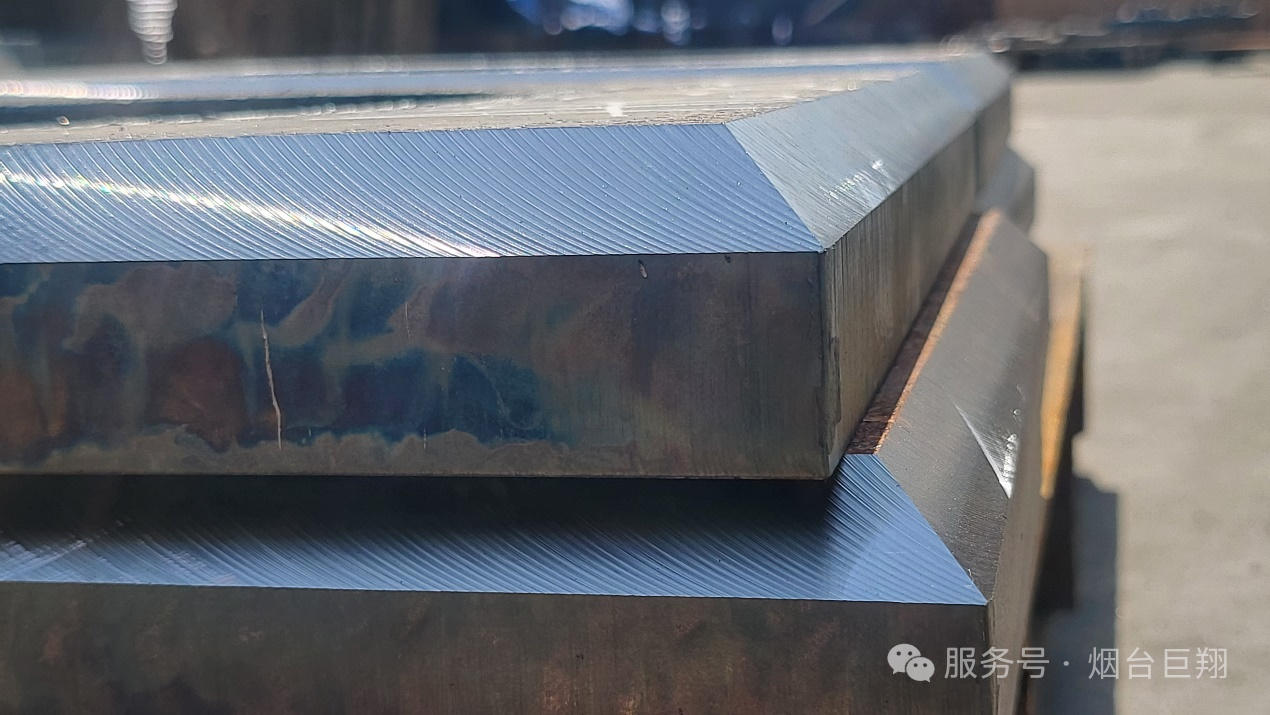

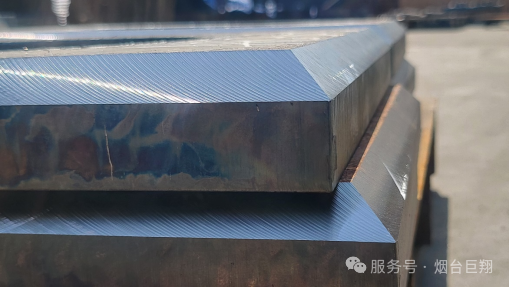

Naizvozvo, simbi ndiro inofanira kudzokororwa kudzvanywa uchishandisa muchina wekuenzanisa uye akawanda seti ekumusoro uye ezasi rollers kubvisa kushushikana kwemukati uye kudzoreredza flatness.

Zvinhu zvakakosha zvekuenzanisa:

· Iyo flatness yesimbi ndiro inofanira kudzorwa mukati ± 2mm/m;

· Mativi ese ari maviri endiro yesimbi anofanirwa kudzvanywa panguva imwe chete kuti adzivise kureverse warping;

· Kune mahwendefa esimbi akasimba (> 20mm), zvakakosha kuaenzanisa kakawanda muzvikamu, uye hazvibviri "kuadzvanya kusvika pasi kamwe chete".

3.2 Chii chinonzi "slope opening"?

Chii chinonzi "beveling"? Nei tichifanira kubhejera mupendero wendiro?

Zviri nyore: kuita weld yakasimba.

Mahwendefa esimbi akajairika ane mipendero yakatwasuka. Kana ivo vakananga butt welded, kudzika kwekupinda hakuna kukwana uye weld haina kugadzikana. Uyezve, iyo simbi haigone kusanganiswa zvizere, izvo zvinotungamira nyore kune hurema hwewelding senge inotonhora welding, slag inclusions, uye pores.

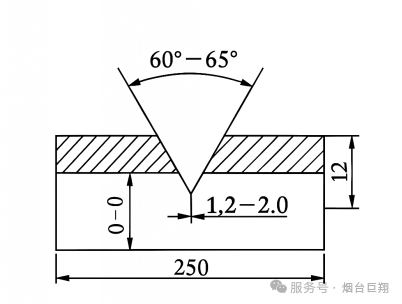

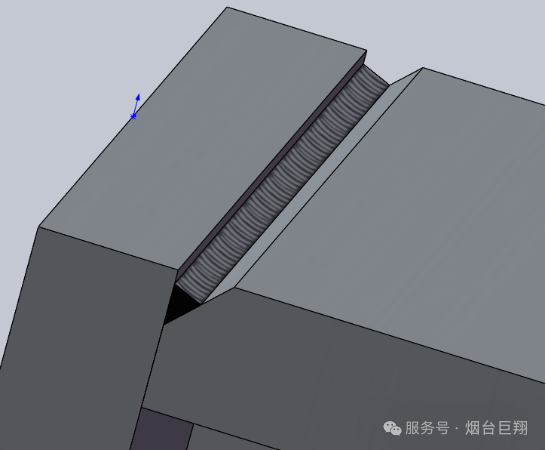

Nokudaro, mupendero weplate unofanira kugadziriswa kuva V-shaped, X-shaped kana U-shaped notch kuitira kuti tsvimbo yewelding kana waya inogona kupinda pasi uye "kuruma" mapepa maviri eplate.

Common Groove mafomu:

Single-sided V-yakaumbwa idivi rimwe rakarerekera, rinoshanda kune ukobvu kushoma kana kuenzana ne20mm; kaviri-mativi X-yakaita mativi maviri symmetrically akarerekera, anoshanda kune ukobvu 20-40mm; K-yakaumbwa uye U-yakaumbwa inoshanda kune mamwe makobvu mahwendefa, ukobvu hombe kupfuura kana kuenzana ne40mm.

Iyo general control ye groove parameters:

Angle: 30 ° ~ 45 ° kune rumwe rutivi, symmetrical angle isingapfuuri 65 °

· Blunt mupendero: 2 ~ 4mm

· "Kuputsika kwekona", "kubvaruka kwemucheto" uye "kupisa-kuburikidza" hazvibvumirwi

Processing nzira:

· Batch yakatwasuka ndiro mupendero → CNC murazvo/plasma beveling yekucheka muchina

· Zvikamu zvemunharaunda zvine chimiro → kabhoni arc gouging + kugaya

· Yakanyanya kurongeka → CNC milling muchina/robhoti beveling yekucheka

3.3 Inonzwisisika beveling maitiro

Iyo inonzwisisika groove process ndeyekugadzirira inonzwisisika yakawanda-layer welding uye kuwedzera solder huwandu uye huwandu hwematanho eiyo weld. Chii chichaitika kana danho iri rikasaitwa zvakanaka?

· Yakakura welding deformation: Iyo shrinkage simba re weld "inodhonza chikamu chose chakamonyana"

· Kusangana kwakaoma: Nzvimbo yegomba haina kurongeka, uye chinongedzo hachigone kuiswa

· Kuneta kutsemuka: Residual stress + welding defects, kutsemuka kwechimiro mukati memakore mashoma.

Kuwedzera mitengo: Kugadzirazve, kukuya, gadzira patsva, kana kukwenya ruoko rwose

Nokudaro, zvinowanzotaurwa mumhizha kuti: "Kana ndiro yacho isina kuenzaniswa uye groove isina kuitwa zvakanaka, pasinei nokuti iyo welder yakanaka sei, inenge isingabatsiri."

Muchirevo chimwe:

"Plate leveling + beveling" inhanho yekutanga yekuvandudza kunaka kwewelding uye pekutangira kuti boom ibve kubva pa "welding inokwanisa" kuenda ku "welding stably".

Zvingasava zvinoyevedza, asi pasina izvozvo, ururami hwose hunozotevera, simba, uye kuchengeteka zvichava kutaura kusina maturo.

Nguva yekutumira: Jun-12-2025